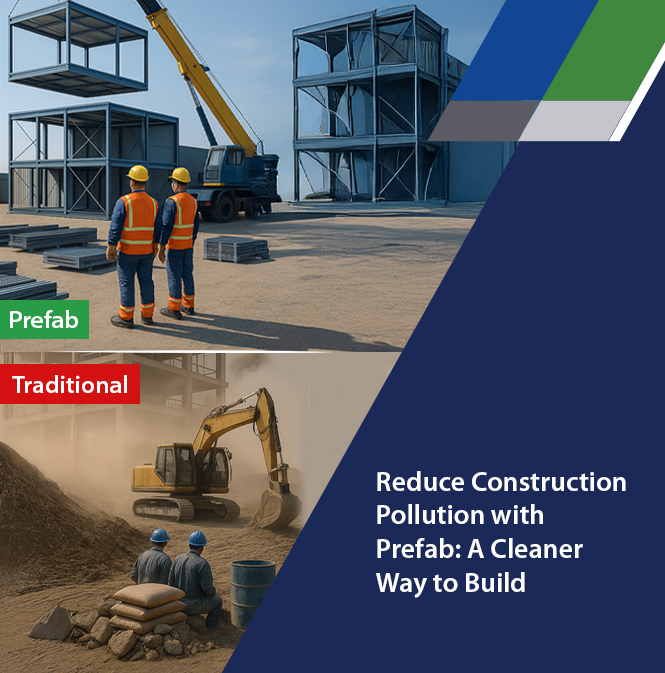

Reduce Construction Pollution with Prefab: A Cleaner Way to Build

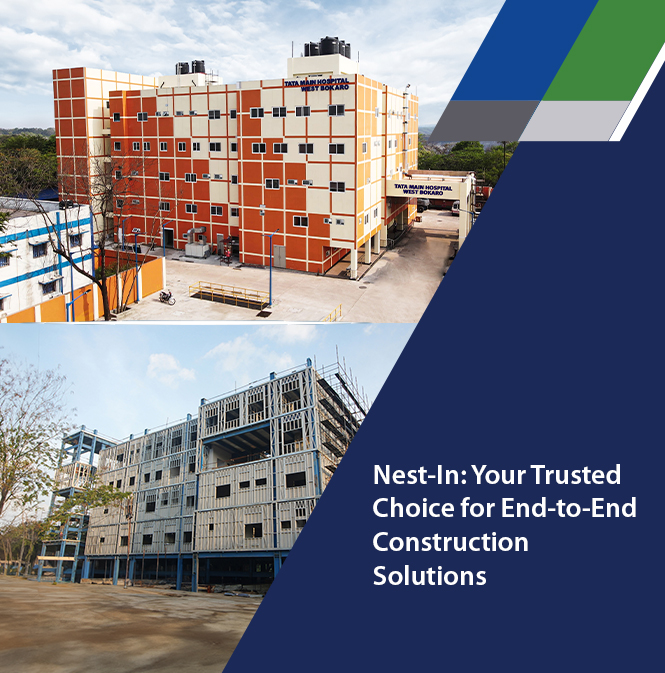

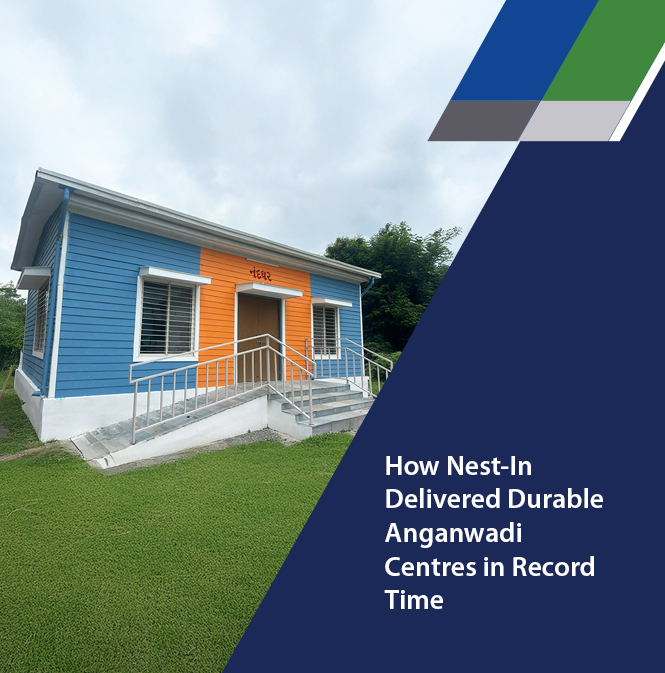

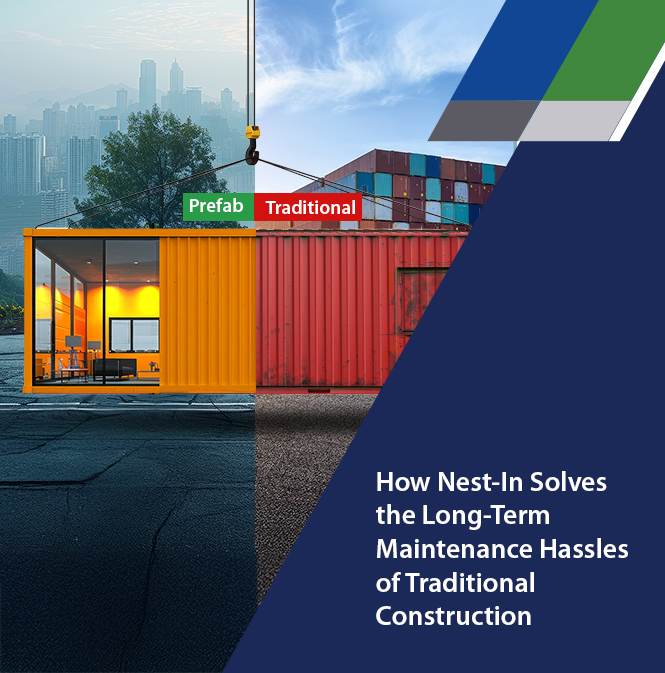

Tata Steel Nest-In is helping transform the way India builds by shifting construction from chaotic sites to controlled factory environments. While traditional methods generate dust, noise, waste, and continuous disturbance, prefab construction offers a cleaner, more responsible approach that supports sustainable development. By moving most construction activities off-site, Nest-In minimises pollution at every stage of the construction cycle.

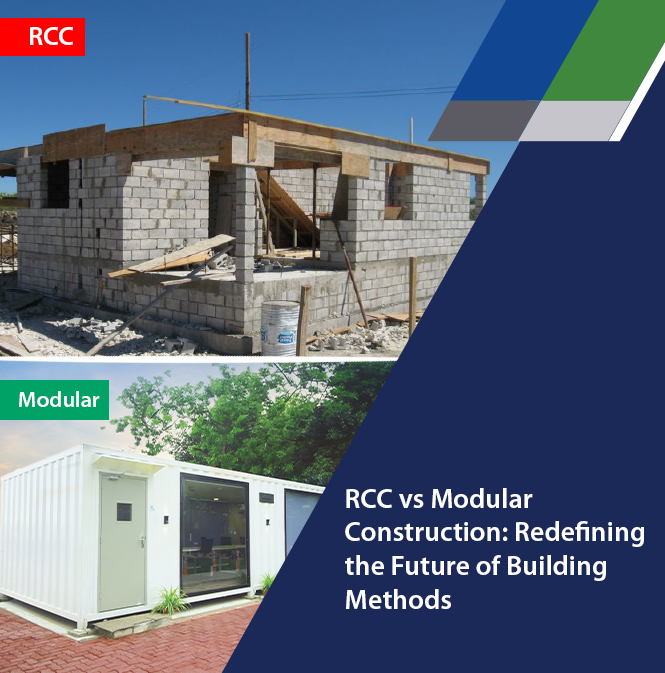

Why Traditional Construction Generates High Pollution

Conventional building heavily depends on on-site activities such as mixing, cutting, drilling and material handling. These processes generate dust, debris, noise, and contaminated runoff, all of which negatively impact surrounding communities and ecosystems.

The unpredictable nature of traditional construction leads to material wastage, inefficient resource use, frequent vehicle movement, further increasing emissions, and environmental strain. As a result, organisations seeking cleaner and more responsible alternatives are increasingly turning to sustainable construction methods to reduce their environmental footprint.

Lower Air Pollution Through Off-Site Manufacturing

One of the most visible forms of construction pollution is airborne dust. Activities such as sand mixing, cement handling, block cutting, and debris movement release large amounts of fine particulate matter. Prefab construction eliminates these on-site processes because all building components are manufactured in a factory using precise, automated machinery. When the finished components arrive at the project location, they are ready for quick and clean assembly.

This shift significantly reduces dust generation and improves overall air quality. The controlled nature of factory production also helps maintain cleaner, safer working environments while supporting more sustainable building practices.

Reduced Noise and Fewer On-Site Disturbances

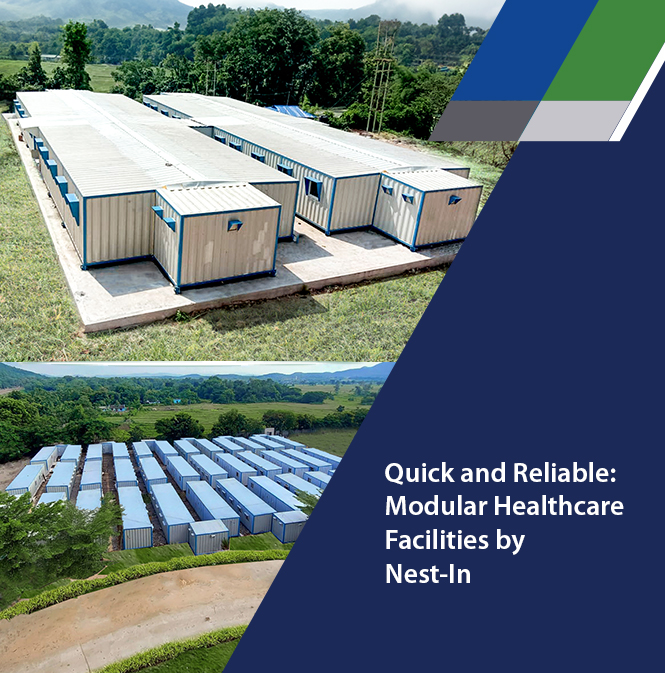

Traditional construction sites often experience constant noise from machinery, drilling and heavy equipment operating throughout the day. With prefab construction, most of this work is shifted to a controlled factory environment. The building components arrive on-site ready to assemble, which greatly reduces the need for loud on-ground activities. This leads to far less noise, creating a quieter and safer environment for workers as well as surrounding communities. This advantage is especially valuable in operational environments such as schools, colleges, and hospitals, where construction must cause minimal disturbance.

Lower Water Pollution and Significantly Lower Water Usage

Traditional construction relies heavily on water for curing, mixing and cleaning, often resulting in wastewater runoff that can contaminate soil and nearby water bodies. Prefab construction avoids these risks by using above-ground dry construction processes. In prefab construction, water is required only during ground preparation and foundation work. The entire superstructure is built using precise, dry methods, ensuring the building process remains clean, controlled, and environmentally responsible. This approach aligns with the principles of eco-friendly construction, reducing resource consumption while maintaining strong structural performance.

Minimised Material Waste Through Factory Precision

Material wastage is common in traditional construction due to inaccurate cutting, rework, breakages, and on-site mishandling. Prefab construction eliminates these inefficiencies through highly controlled factory production. Each component in the prefab structure is engineered with exact measurements, ensuring optimal material usage and minimal waste.

By reducing offcuts, breakage and on-site debris, Nest-In helps organisations maintain cleaner project sites while supporting long-term sustainability goals. Factory precision also ensures consistent quality and improved structural performance across every build.

Reduced Transport Movements and Lower Emissions

In conventional projects, the continuous delivery of sand, bricks, cement, and aggregates results in high traffic, dust generation, and increased vehicular emissions. Prefab construction significantly reduces transport frequency because components are manufactured off-site and transported to the location when they are ready for final assembly. This drastically lowers the number of vehicle trips required. Fewer transport movements help create cleaner, safer and more efficient project sites.

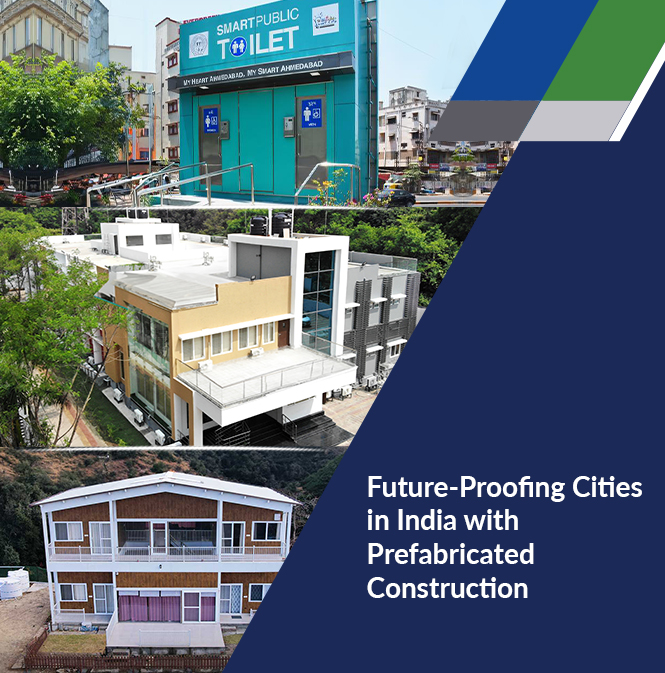

A Smarter, Greener, Future-Ready Construction Approach

Prefab construction aligns naturally with modern sustainability goals by reducing pollution and using resources more efficiently. With most work happening in controlled factory environments, Nest-In minimises material wastage, limits transport-related emissions and supports cleaner, healthier workspaces.

Factory-built components and rapid on-site assembly further reduce on-ground disturbance and lower the overall environmental footprint. This approach not only accelerates construction but also enables more responsible, eco-conscious project delivery.

Conclusion

Prefab construction offers a cleaner and smarter alternative to traditional on-site construction. By cutting dust, noise, waste, water usage and vehicle movement, Nest-In sets a higher benchmark for environmentally responsible construction.

With controlled factory manufacturing and dry building methods, prefab is redefining how sustainable infrastructure is built, helping organisations create spaces that are efficient, safe and future-ready.

For cleaner, faster and more sustainable construction, choose Nest-In. Connect with us at 1800 208 8200 or visit www.nestin.co.in to know more.

Posted in Nest-In on Nov 20, 2025.

Contact Us

Recent Post

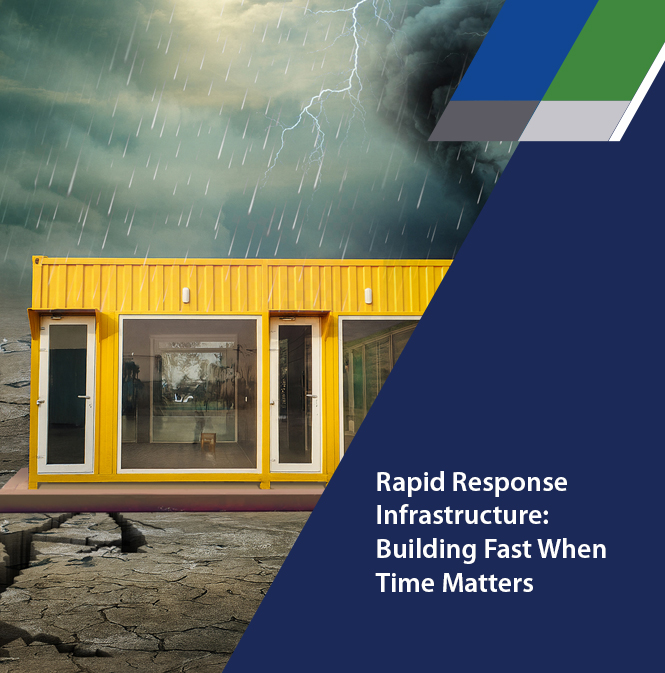

Climate-Resilient Construction: The Growing Demand For Weather-Ready Prefab Spaces

Stylish Modular Spaces Built for Every Terrain

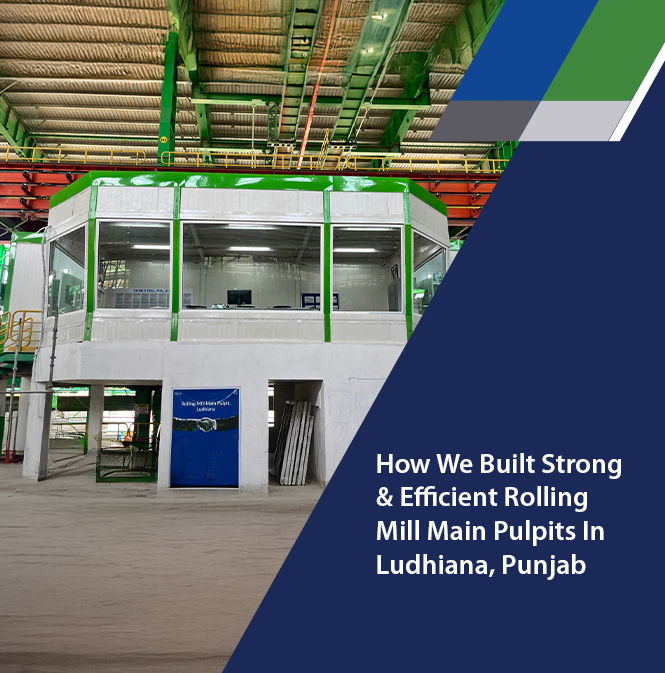

How We Built Strong & Efficient Rolling Mill Main Pulpits In Ludhiana, Punjab

Climate Is Changing. Our Buildings Must Too: How Prefab Creates A Greener, Safer Future

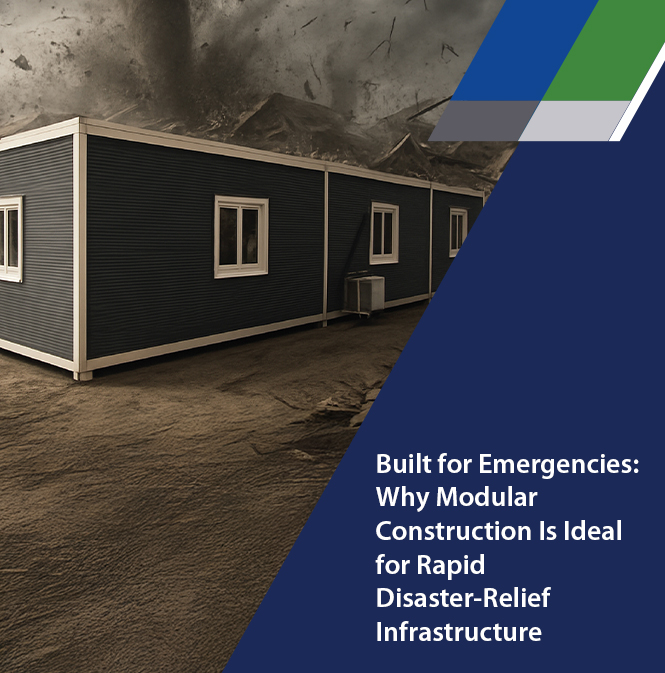

Built for Emergencies: Why Modular Construction Is Ideal for Rapid Disaster-Relief Infrastructure

Category

- Nest-In 108

- HabiNest 65

- MobiNest 124

- Nestudio 28

- EzyNest 21

- Smart EzyNest 6

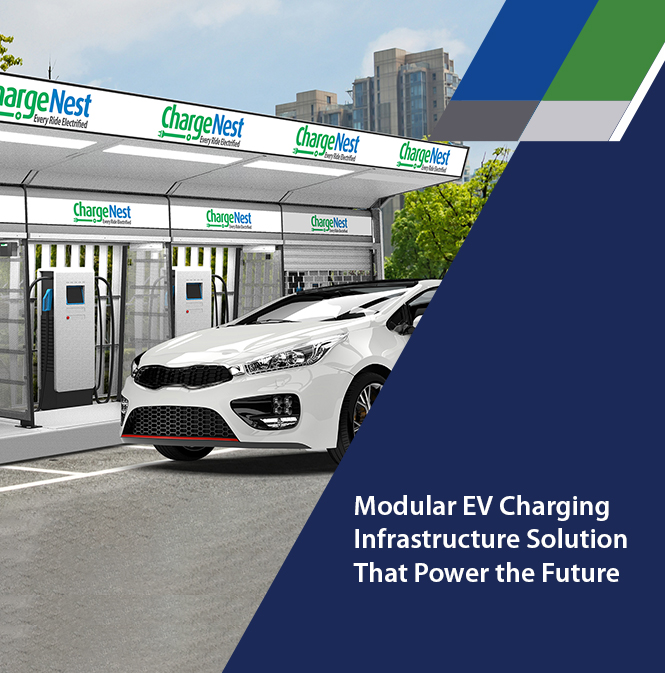

- ChargeNest 7

- Covid Offerings 4

- Brand 7

Add comment