Overcoming Project Delays: How Prefab Construction Keeps Timelines on Track

In the construction industry, project delays often result from unpredictable weather, material shortages and site-related constraints. These setbacks not only slow down progress but also impact delivery commitments. Nest-In from the house of Tata Steel addresses these challenges through its advanced prefabricated construction solutions that offer speed, consistency and reliability. By moving key processes off-site and maintaining stringent quality control, Nest-In ensures faster execution and dependable timelines for every project.

Predictable Timelines with Off-Site Manufacturing

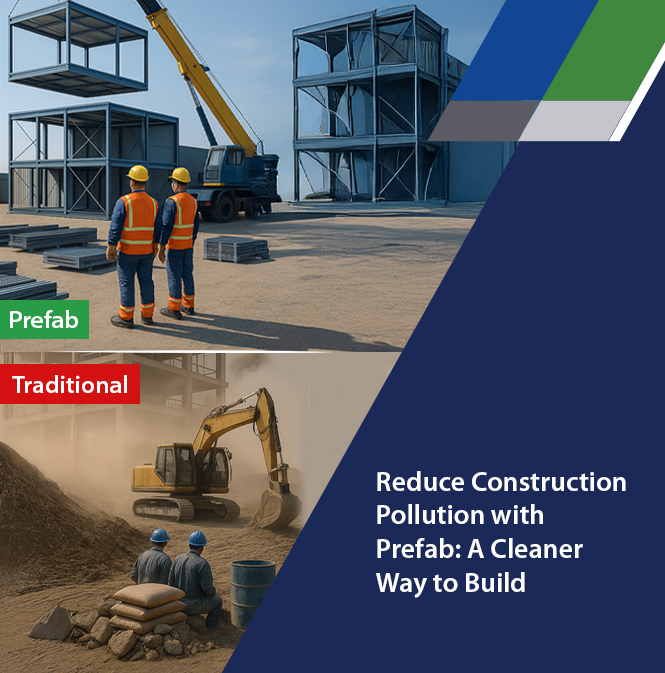

In prefab construction, most of the work happens off-site. The structural and architectural components are manufactured in state-of-the-art factories while site preparation is done simultaneously. This parallel workflow drastically reduces total construction time, enabling faster project completion without compromising quality. The factory-controlled environment ensures precision and standardisation, eliminating common site-related delays and giving developers a clearer picture of delivery timelines right from the start.

Uninterrupted Progress, Regardless of Weather

Unlike traditional construction, where weather can affect work for days or weeks, prefab construction ensures consistent progress. Since the building components are fabricated in a factory setting, the prefab construction process remains unaffected by rain, wind or temperature fluctuations. Once these building components are ready, they are transported to the site for quick assembly. This process allows projects to move forward regardless of environmental conditions, ensuring continuity and avoiding downtime caused by weather disruptions. For clients, this means reliable scheduling and a seamless construction journey.

Precision Planning and Quality Control

At Nest-In, every structure is engineered for strength, quality and long-term performance. Built with premium Tata Steel under ISO 9001:2015-certified processes, our prefab construction solutions maintain dimensional accuracy, precision and structural integrity. The controlled manufacturing process ensures uniform standards, reducing the risk of rework or on-site corrections that typically extend project timelines. This meticulous approach allows clients to plan confidently, knowing each component is built to specification and ready for efficient on-site integration.

Faster Execution

In prefab construction, the factory-built components are transported to the site for quick assembly, allowing projects to be completed 2x faster than traditional structures. Reduced on-site labour, minimal waste and efficient logistics further accelerate project delivery.

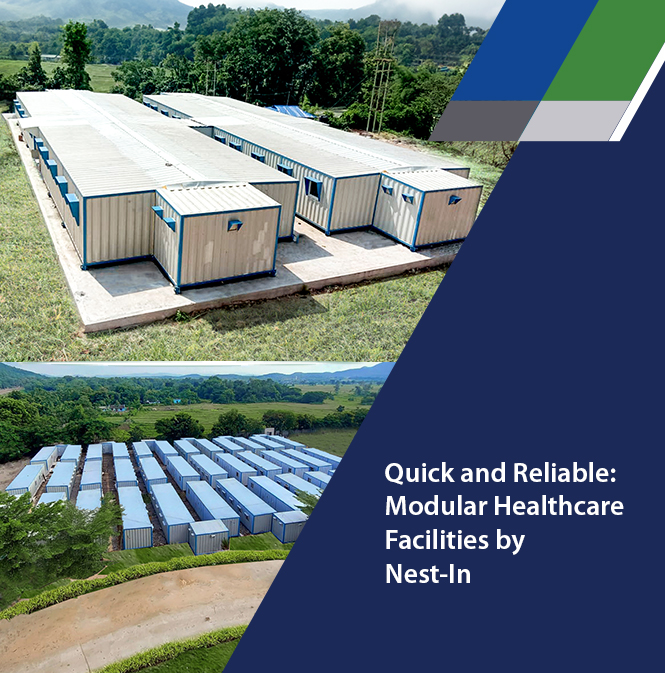

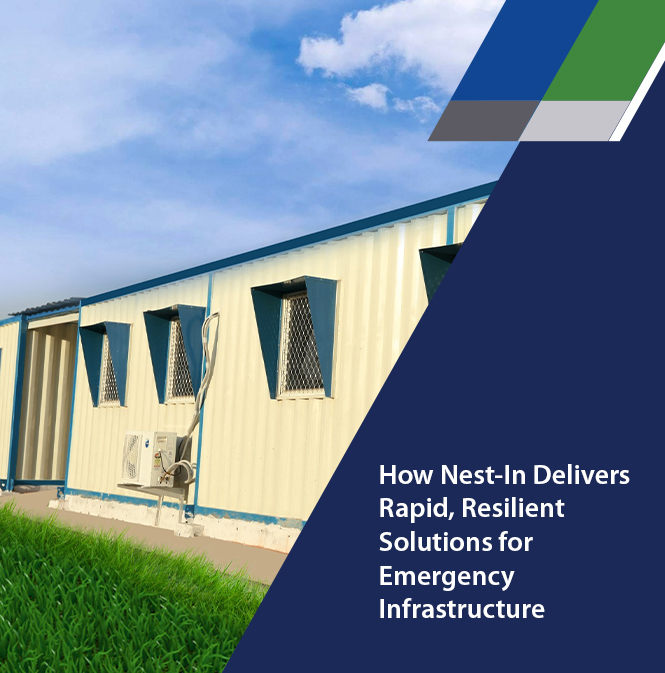

For projects requiring immediate readiness, Nest-In’s modular construction solutions offer even faster deployment. Our modular structures are built entirely in a factory. Once ready, these modular units are transported to the site for quick installation, requiring only basic electrical and plumbing work. The plug-and-play nature of these modular spaces makes them ideal for emergency facilities, remote locations or fast-track commercial developments.

Long-Term Reliability

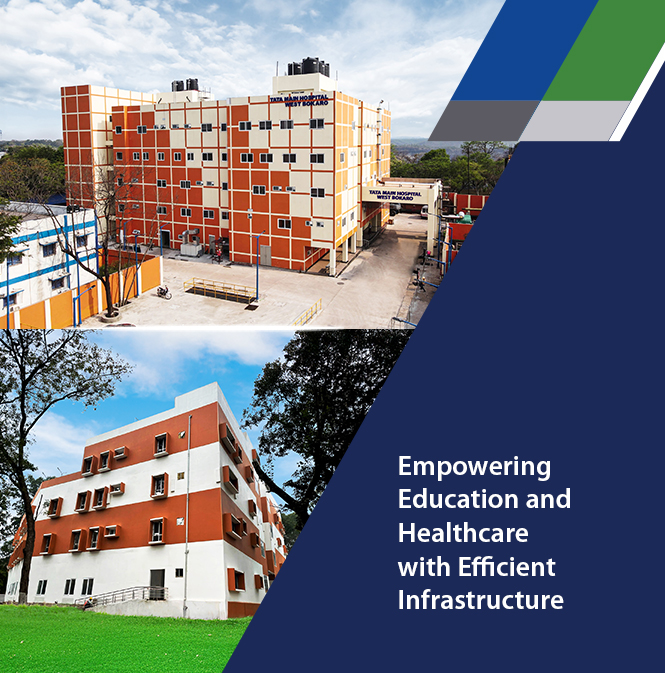

Nest-In’s prefabrication approach not only saves time but also enhances long-term reliability. Factory-controlled production eliminates inconsistencies caused by varying on-site conditions, ensuring that each unit, from modern prefab homes to industrial structures, meets the same quality standards. This precision-driven process also supports safer working environments and lower site congestion, allowing multiple phases of construction to progress smoothly.

Furthermore, steel-based structures provide unmatched strength and resilience. These prefab structures are built using corrosion-resistant materials that withstand environmental damage, ensuring durability over decades.

Building for the Future: Smart, Reliable & Sustainable

Every Nest-In project embodies the principles of smart construction, such as speed, sustainability and structural performance. By leveraging off-site manufacturing and modern construction techniques, our prefab structures consume fewer resources and generate less waste. Compared to conventional building methods, Nest-In’s prefab construction process uses 48% less freshwater, 65% less material sourcing, and results in 53% lower greenhouse gas emissions. This sustainable, technology-led approach is shaping the future of fast and dependable construction across India’s industrial, residential and institutional sectors.

Conclusion

Delays no longer have to define the construction process. With Nest-In’s prefabrication expertise, projects are delivered on time, no matter the complexity or environment. Through off-site precision, reduced dependency on weather and efficient planning, Nest-In continues to set benchmarks for reliability and speed.

For businesses and developers looking for a smarter, faster way to build, prefab is the way forward and Nest-In is leading the transformation.

Build with confidence and stay on schedule with Nest-In’s prefab construction solutions. Connect with us at 1800 208 8200 or visit the link: https://www.nestin.co.in/ to explore more.

Posted in Nest-In on Nov 06, 2025.

Contact Us

Recent Post

Climate-Resilient Construction: The Growing Demand For Weather-Ready Prefab Spaces

Stylish Modular Spaces Built for Every Terrain

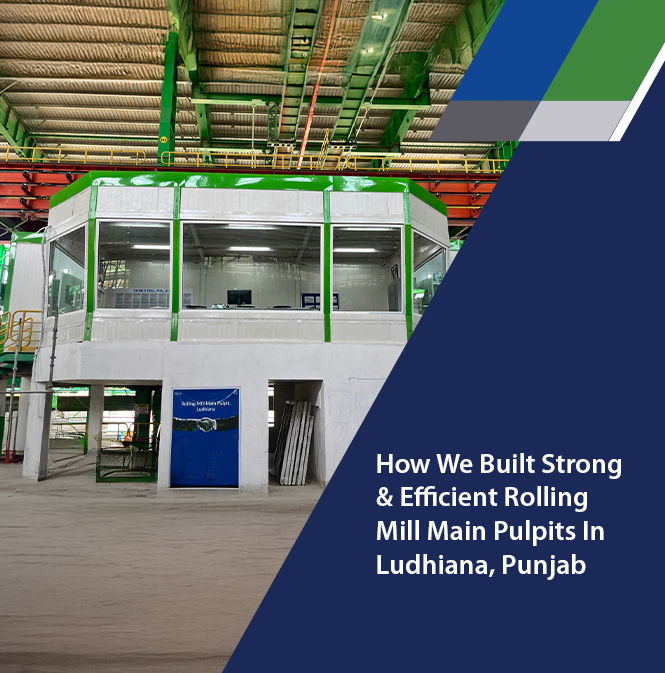

How We Built Strong & Efficient Rolling Mill Main Pulpits In Ludhiana, Punjab

Climate Is Changing. Our Buildings Must Too: How Prefab Creates A Greener, Safer Future

Built for Emergencies: Why Modular Construction Is Ideal for Rapid Disaster-Relief Infrastructure

Category

- Nest-In 108

- HabiNest 65

- MobiNest 124

- Nestudio 28

- EzyNest 21

- Smart EzyNest 6

- ChargeNest 7

- Covid Offerings 4

- Brand 7

Add comment