Modular Construction in Prefab: A Modern Approach to Building

In today's world, the need for innovative solutions has become a necessity in every aspect of people’s lives. The reason is people are looking for new technologies, which are fast, efficient and make life easy. The construction industry is also looking for such solutions to make the way we build not only swift and hassle-free, but also better for the planet. With the monumental rise in number of construction projects across India, the demand for faster, smarter and more sustainable infrastructure solutions is stronger than ever.

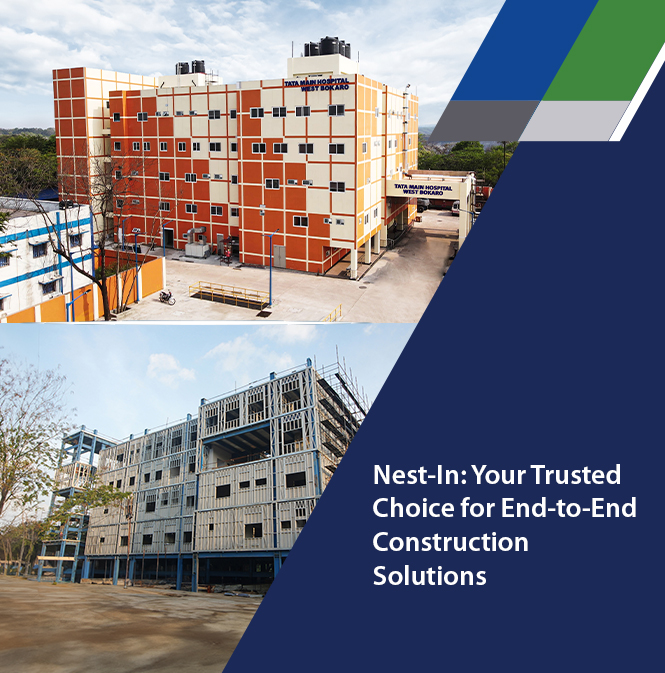

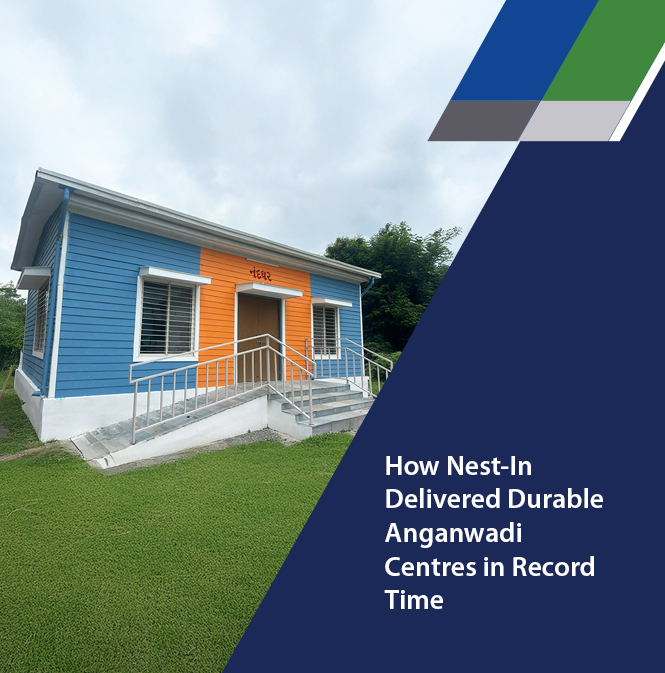

One such methods which is changing the face of this industry is modular construction – a method mastered by Nest-In, an innovative construction brand from the house of Tata Steel. While traditional construction methods often struggle to keep pace with the growing need for high-quality infrastructure delivered within tight deadlines, modular construction solutions by Nest-In offer a unique blend of speed, precision and flexibility. It is now redefining the future of the construction industry and is beneficial for businesses and communities to scale up the infrastructure development.

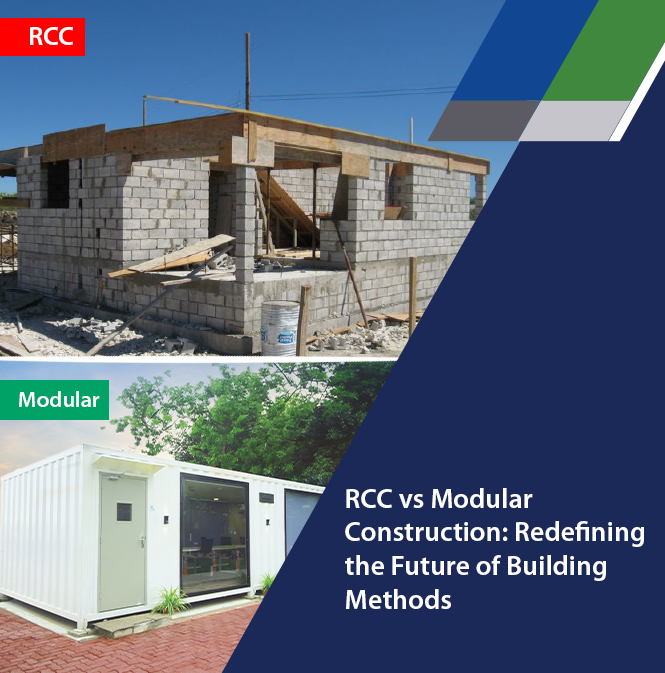

What Is Modular Construction?

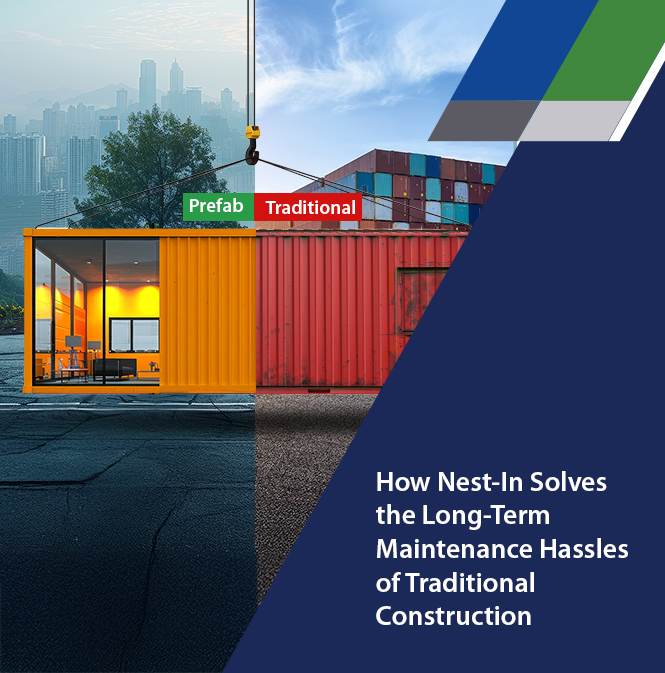

Modular construction is a building method where structures are already prefabricated in a controlled factory environment off-site and then transported to the site for quick and seamless installation (plug-and-play). While most companies refabricate old shipping containers as modular structures, Nest-In builds them from scratch with Tata Steel – ensuring quality and durability.

These plug-and-play modular units are ready to install, requiring only the plumbing and electrical work to be done off-site. Since these are factory-manufactured, their timelines are unaffected by the weather conditions, ensuring minimal disruption and faster project completion.

Faster Project Timelines

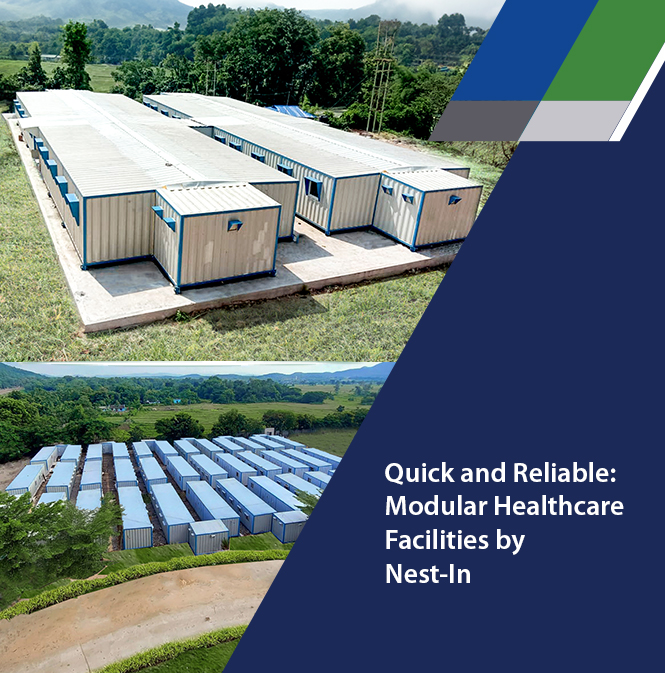

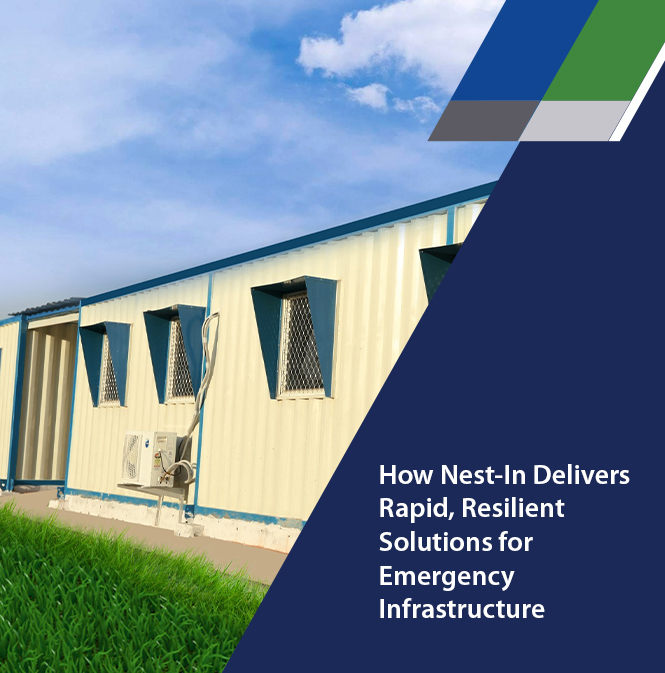

Project timelines are drastically reduced by using this prefab construction technology. Modular units are built off-site simultaneously while site preparation is underway. Off-site and on-site construction phases go hand in hand which significantly reduces the project timelines. This allows for faster project completion, which is also a useful factor for building emergency infrastructure as compared to conventional methods.

Factory-Controlled Manufacturing for Efficiency and Precision

The factory-controlled manufacturing process of modular units ensures consistent quality and precision throughout the construction process. Nest-In being an ISO-certified (ISO 9001:2015) company follows a standard manufacturing process, ensuring quality control at every step. By eliminating the variability often seen with on-site construction, such as weather disruptions or inconsistent labour, modular construction guarantees adherence to quality standards at every step. Manufactured with the use of advanced prefab construction technology, these modular units ensure faster project completion with exceptional efficiency.

Seamless Installation Process

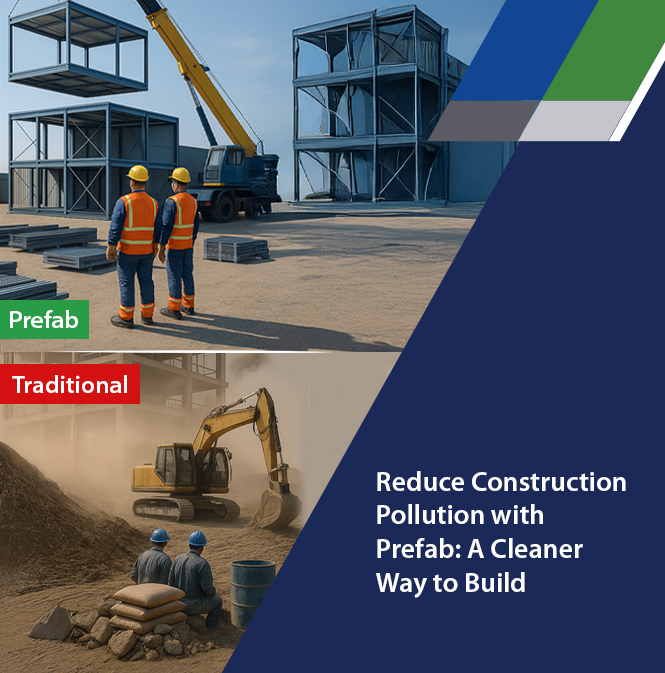

The prefabricated modular units are transported from factories to the site, reducing labour requirements and minimising disruption to surrounding areas and then quickly installed on-site. This seamless installation process not only saves time but also enhances safety and reduces environmental impact compared to traditional construction.

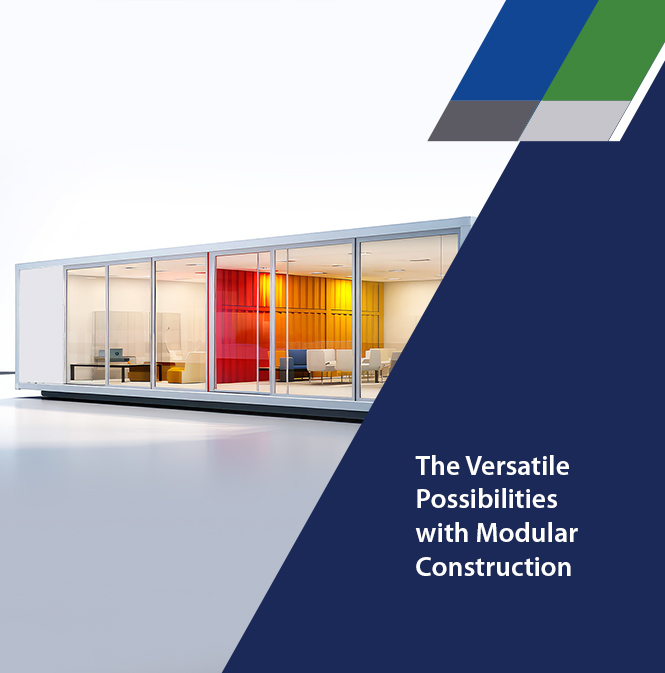

Flexible Design and Expansion

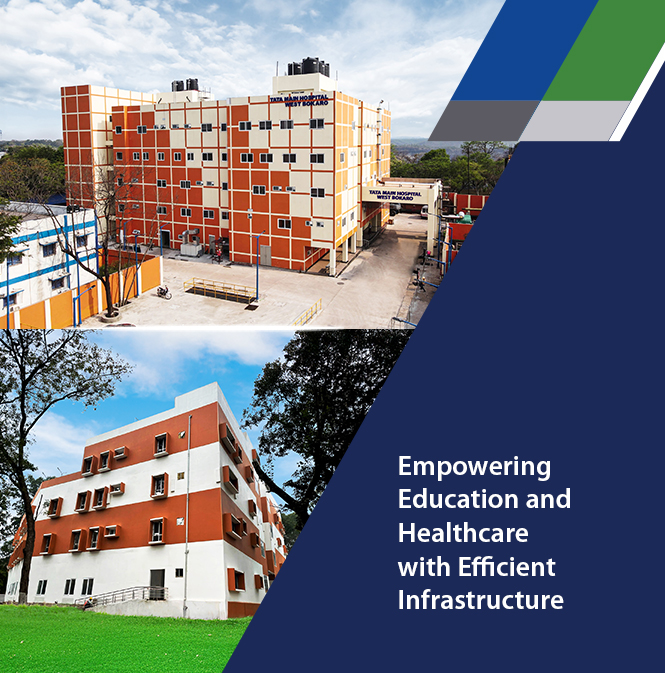

Flexibility is an inherent characteristic of this sustainable modular construction method. As per the ever-evolving needs, design flexibility plays a vital role in construction. With expansion plans such as adding new classrooms to a school, expanding hospital wings, or scaling up industrial infrastructure, Nest-In's modular construction solutions offer scalability and complete customisation of spaces as per your requirements, all without lengthy downtime or major disruption.

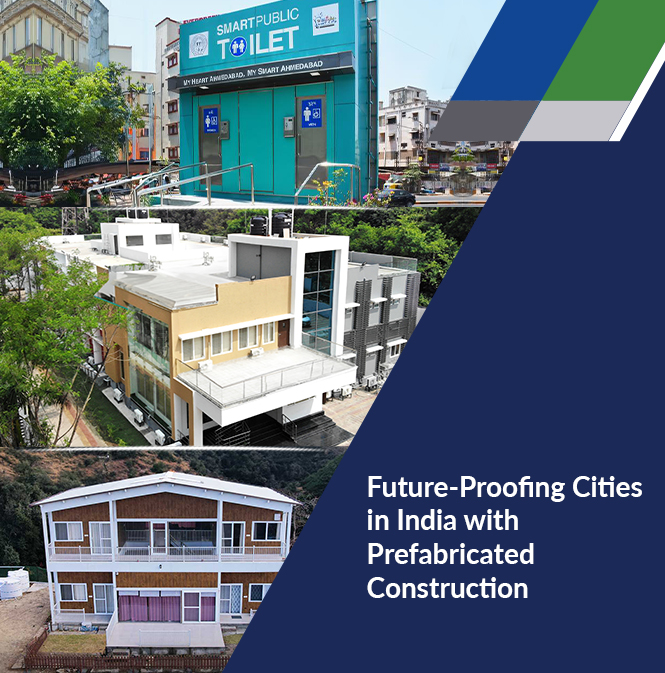

Versatile Applications Across Sectors

From schools and hospitals to commercial and industrial requirements, the versatility of Nest-In's modular construction solutions make them ideal for a wide range of applications across diverse sectors. In education, it enables the rapid development of fully equipped schools and training centres. Healthcare facilities benefit from quickly deployable modular hospitals and clinics that meet stringent quality and safety standards. Commercial enterprises leverage modular designs for office spaces, retail outlets and mixed-use developments. Meanwhile, industries turn to pre-engineered buildings for warehouses, manufacturing plants and other critical industrial infrastructure needs — all delivered with speed, quality and sustainability at the core.

Conclusion – Building Smarter with Modular Construction

As speed, precision and sustainability define the future of construction, Nest-In’s modular approach is the answer to the modern infrastructure demands of today and tomorrow. With its factory-controlled processes, consistent quality and precision are assured in every project along with shorter timelines and hassle-free construction. With flexibility, expansion, versatility and adaptability, sustainable modular construction emerges as the definitive path forward.

Partner with Nest-In today and unlock the power of modular innovation to fast-track your next project with unmatched confidence, speed and precision. Connect with us at 1800 208 8200 or visit our website: https://www.nestin.co.in/ to know more.

Posted in Nest-In on Jun 23, 2025.

Contact Us

Recent Post

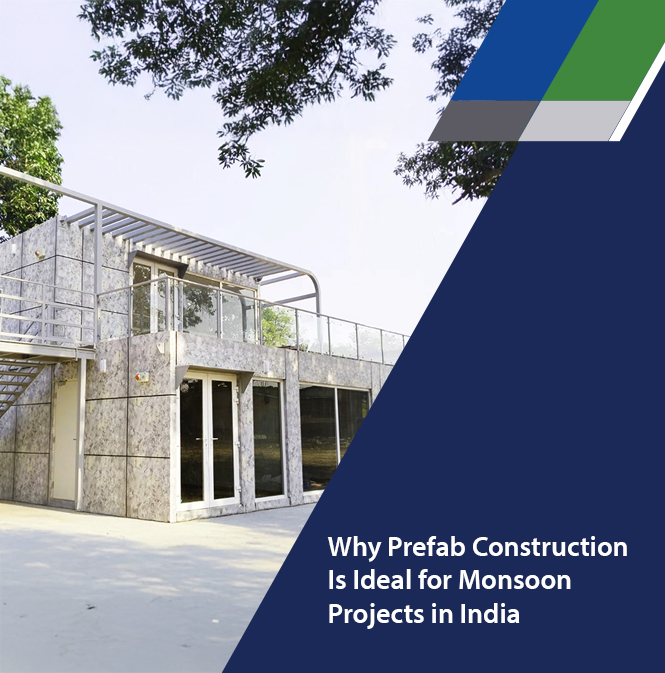

Climate-Resilient Construction: The Growing Demand For Weather-Ready Prefab Spaces

Stylish Modular Spaces Built for Every Terrain

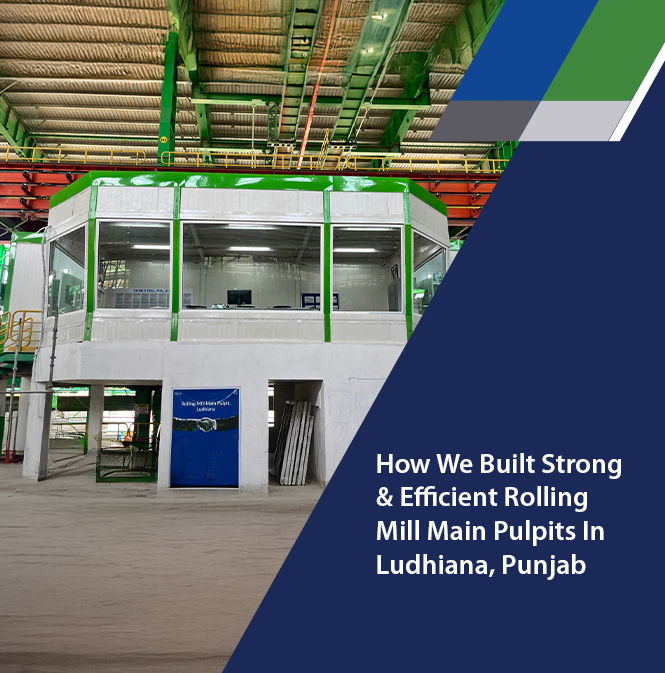

How We Built Strong & Efficient Rolling Mill Main Pulpits In Ludhiana, Punjab

Climate Is Changing. Our Buildings Must Too: How Prefab Creates A Greener, Safer Future

Built for Emergencies: Why Modular Construction Is Ideal for Rapid Disaster-Relief Infrastructure

Category

- Nest-In 108

- HabiNest 65

- MobiNest 124

- Nestudio 28

- EzyNest 21

- Smart EzyNest 6

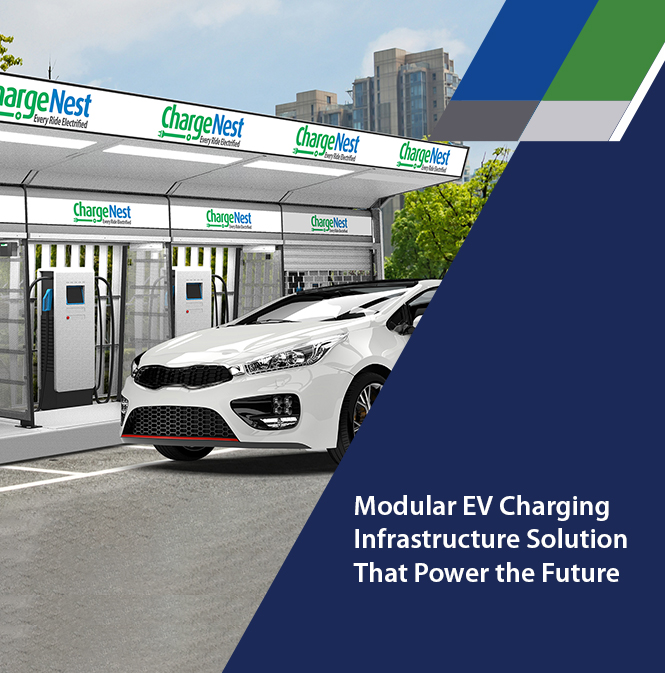

- ChargeNest 7

- Covid Offerings 4

- Brand 7

Add comment