A Closer Look at Nest-In's Methods: Types of Prefab Construction Technologies

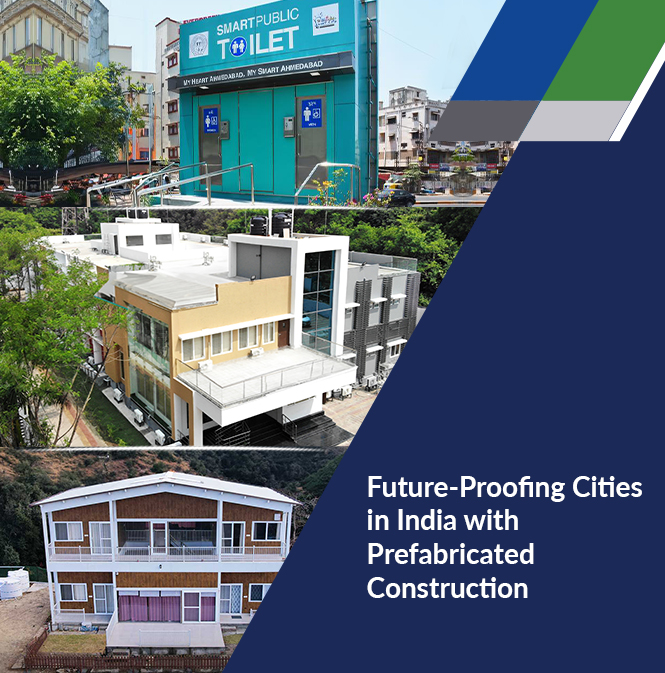

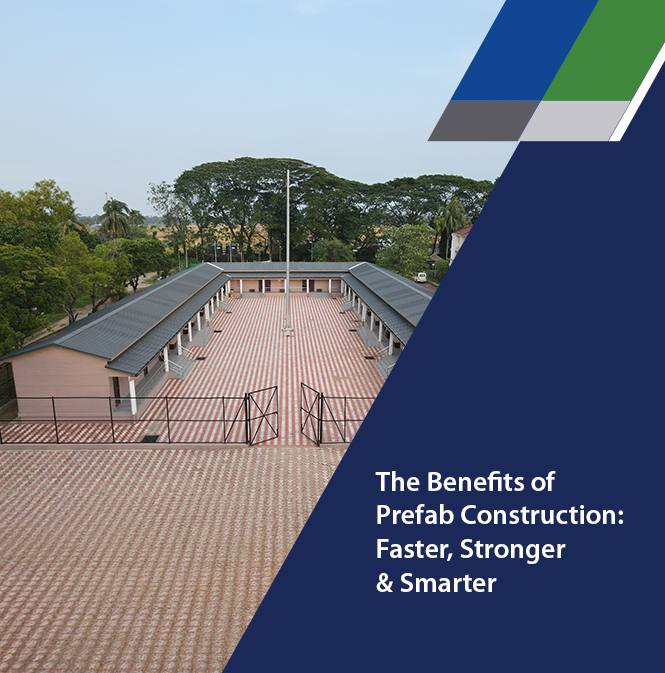

Prefab construction technologies are reshaping how structures are built, offering speed, precision and flexibility. To cater to the challenges faced by traditional construction methods, game-changing prefab construction technologies have evolved in recent years and are making their presence vital in the construction industry. Interestingly, these technologies are reshaping how infrastructure, business places and individual spaces are built.

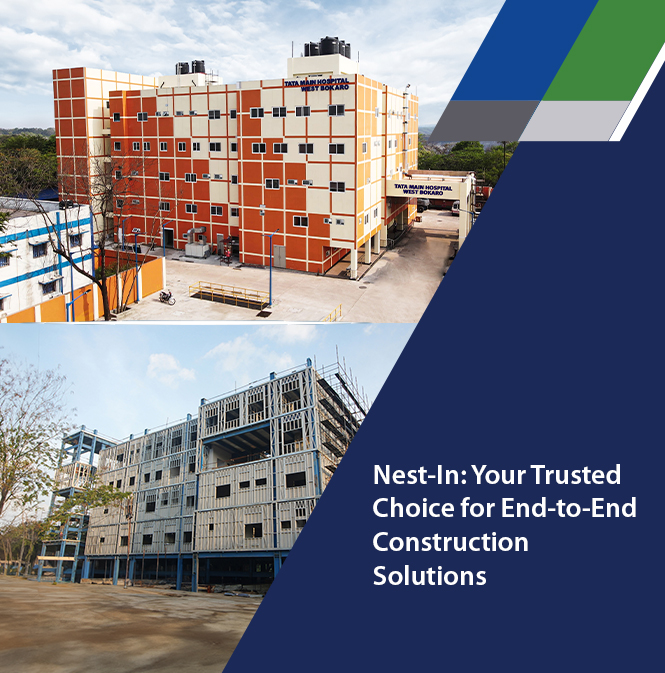

Greater speed, precision and flexibility are a few of the characteristics of these new construction technologies to deliver the projects in the desired timeline, all while making the process more sustainable. Compared to traditional construction methods, prefab construction techniques streamline building processes, minimise site disruptions and ensure consistent quality. Nest-In from the house of Tata Steel is one of the most prominent brands in India that are changing the face of construction with their advanced prefab construction solutions that cater to diverse infrastructure needs across industries.

Nest-In’s Technology-Driven Construction Methods

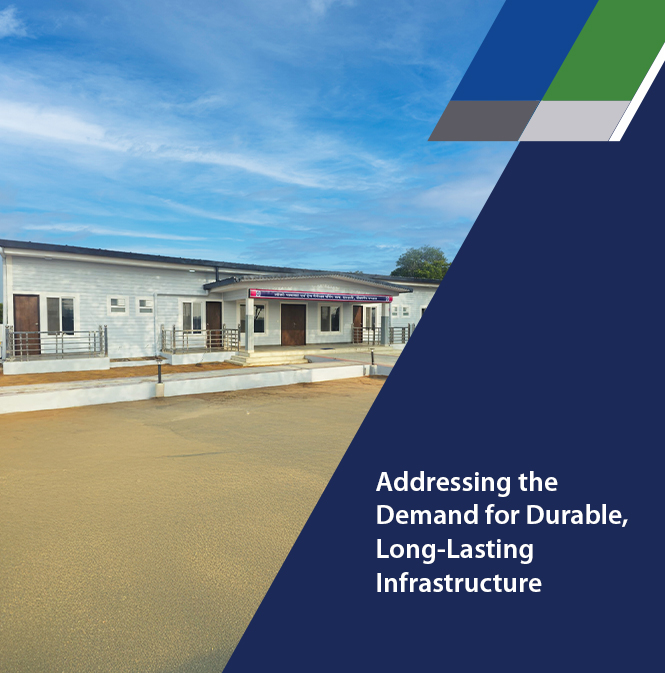

A leader in prefabricated construction solutions, Nest-In is using innovation and precision engineering to build spaces, which helps deliver infrastructure with speed, long-lasting durability and flexibility. Consistent quality, minimum delays and adaptability of various site requirements makes the brand a trusted partner for scalable and efficient building solutions.

Let’s explore Nest-In’s key prefab construction technologies:

LGSF (Light Gauge Steel Frame) Construction

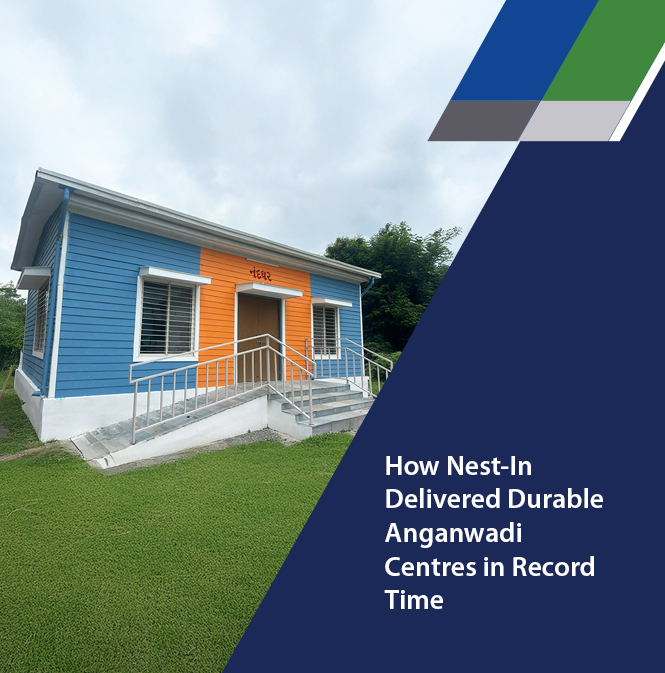

Light Gauge Steel Framing (LGSF) is a modern construction method that uses cold-formed Galvalume steel to build the framework of a structure. These steel-based structures are lightweight yet exceptionally resilient, offering numerous advantages over traditional construction methods. The LGSF building components are prefabricated off-site in a factory-controlled environment, ensuring faster on-site assembly and reduced construction time.

LGSF is highly resistant to rust, corrosion and pests, ensuring long-term durability. Additionally, the steel used is 100% recyclable, making it a sustainable option. This method is versatile and suitable for a wide range of applications, including residential, commercial and industrial buildings.

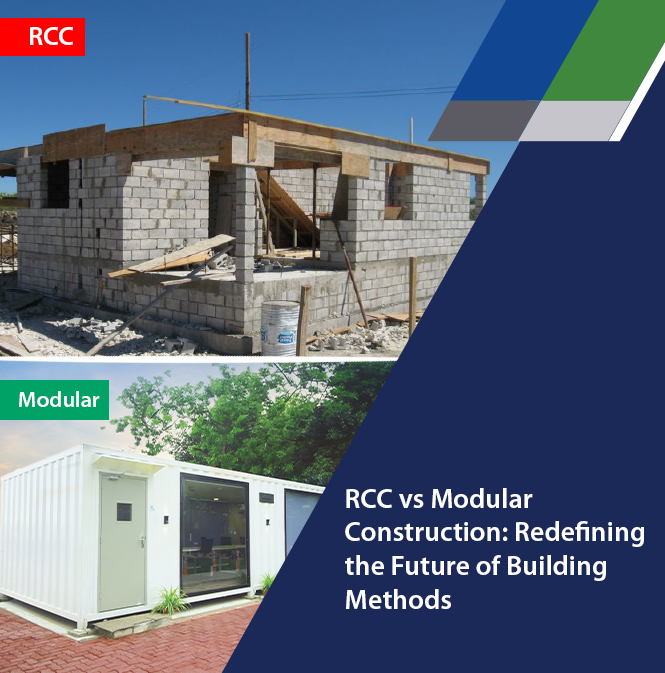

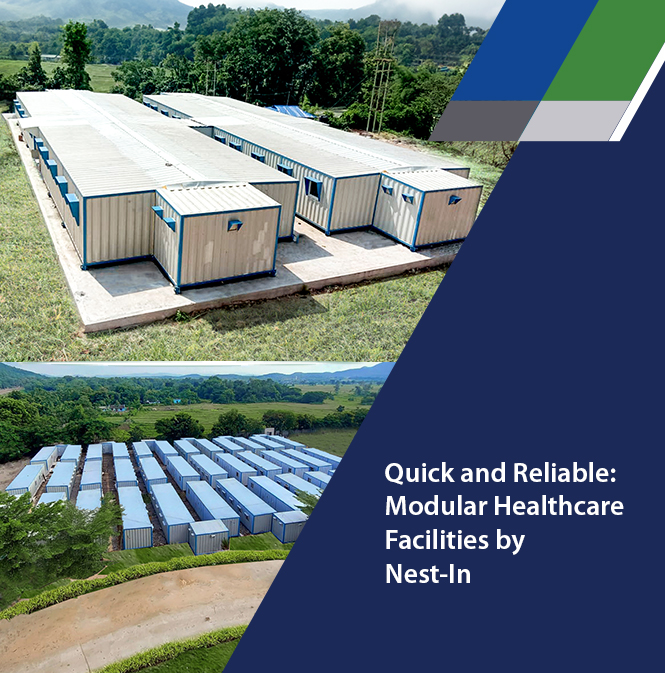

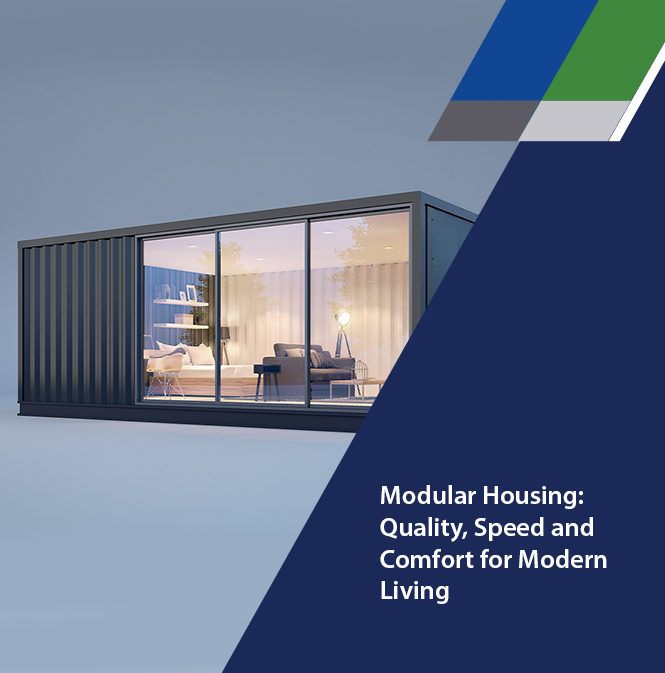

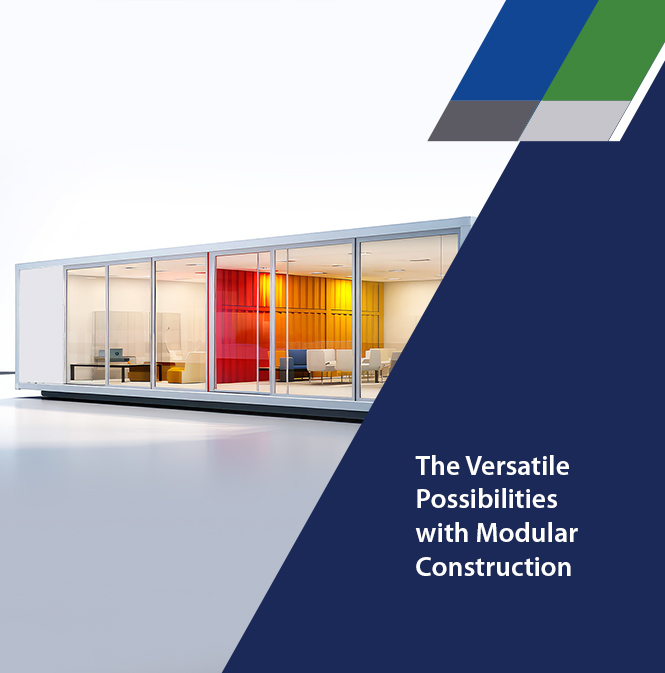

Modular Construction

In modular construction, entire building modules are fabricated off-site from scratch using Tata Steel in a controlled factory setting. These factory-built modular units are then transported and installed on-site with remarkable speed. This innovative approach significantly reduces construction timelines and minimises disruptions at the project location. The controlled factory environment and use of steel as the construction material also ensures consistent, high-quality construction, unaffected by weather related delays or on-site variability.

Hybrid Construction

Hybrid construction offers a smart blend of robustness and efficiency by combining hot-rolled (HR) steel columns and beams for the primary structural framework with cold-rolled (CR) steel for the secondary section. Light Gauge Steel Framing (LGSF) is used for interior and exterior filler walls, which are clad with fiber cement boards to achieve a brick-and-mortar-like finish. This hybrid approach brings together speed, strength and aesthetic appeal, making it ideal for modern construction needs.

Panelised Construction

In panelised construction, prefabricated tubular columns and beams form the framework, which is then clad with factory-finished sandwich panels. These panels consist of a core made of polyurethane foam or mineral wool, enclosed by pre-painted Galvalume sheets on both sides. This system offers excellent thermal insulation, fire resistance and quick assembly, making it ideal for industrial buildings, warehouses and temporary structures that demand efficient, factory-manufactured modular units.

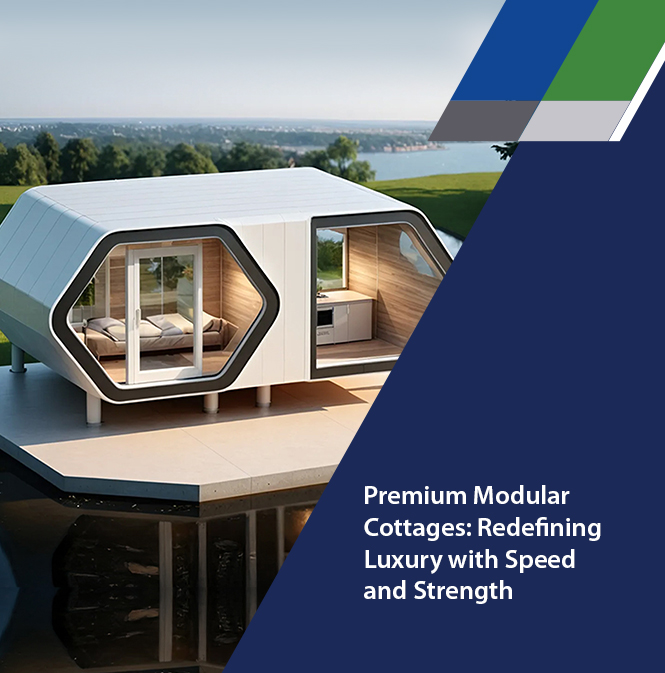

3D Volumetric Construction

3D volumetric construction takes modularity to the next level by manufacturing complete, pre-finished units off-site. These modules are then vertically stacked on-site to form the entire building structure. This method drastically shortens construction timelines while maintaining superior quality and precision. The high degree of off-site construction reduces on-site labour, enhances safety and delivers a truly high-quality construction experience.

Application-based Technology Selection

What sets Nest-In apart is its consultative approach to project planning. Each construction method is carefully selected based on the specific project’s objectives, site conditions and deadlines. Whether it’s a healthcare centre that needs rapid deployment, a commercial space requiring design flexibility or a residential project focused on durability, Nest-In provides the most appropriate prefab construction solutions for every need.

As the demand for efficient, sustainable and reliable infrastructure continues to grow, Nest-In remains committed to delivering cutting-edge prefab construction solutions. Its comprehensive portfolio of innovative construction solutions ensures that every client receives high-quality construction tailored to their exact requirements. With Nest-In, businesses and organisations can confidently embrace the future of construction, knowing they are supported by industry-leading expertise and innovation.

Looking to build smarter and faster? Connect with us at 1800 208 8200 or visit our website: https://www.nestin.co.in/ to know more.

Posted in Nest-In on Jun 26, 2025.

Contact Us

Recent Post

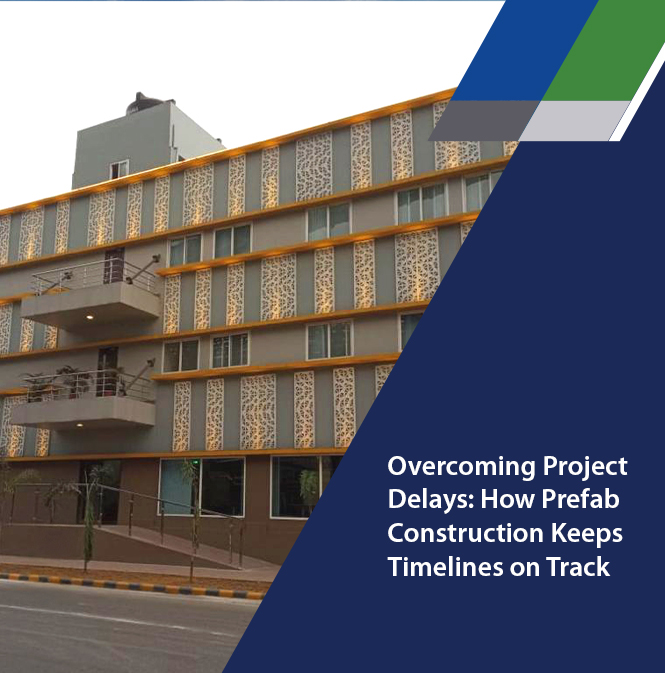

Climate-Resilient Construction: The Growing Demand For Weather-Ready Prefab Spaces

Stylish Modular Spaces Built for Every Terrain

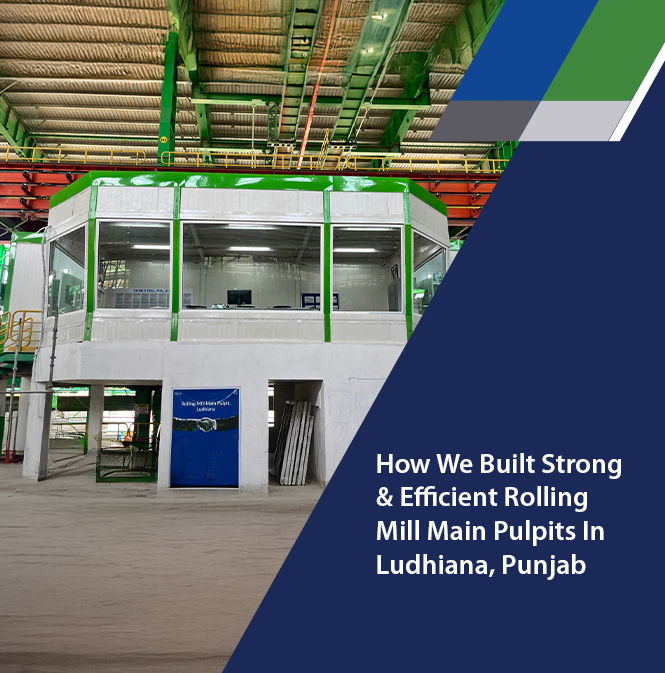

How We Built Strong & Efficient Rolling Mill Main Pulpits In Ludhiana, Punjab

Climate Is Changing. Our Buildings Must Too: How Prefab Creates A Greener, Safer Future

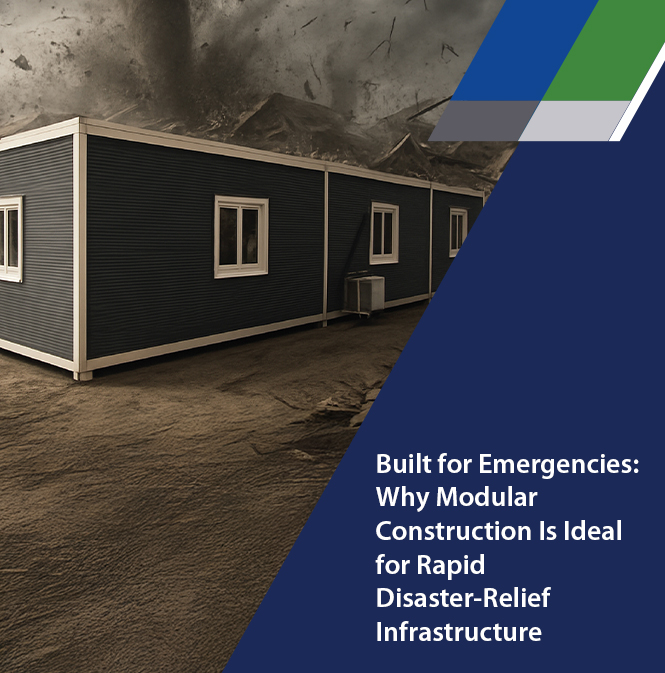

Built for Emergencies: Why Modular Construction Is Ideal for Rapid Disaster-Relief Infrastructure

Category

- Nest-In 108

- HabiNest 65

- MobiNest 124

- Nestudio 28

- EzyNest 21

- Smart EzyNest 6

- ChargeNest 7

- Covid Offerings 4

- Brand 7

Add comment