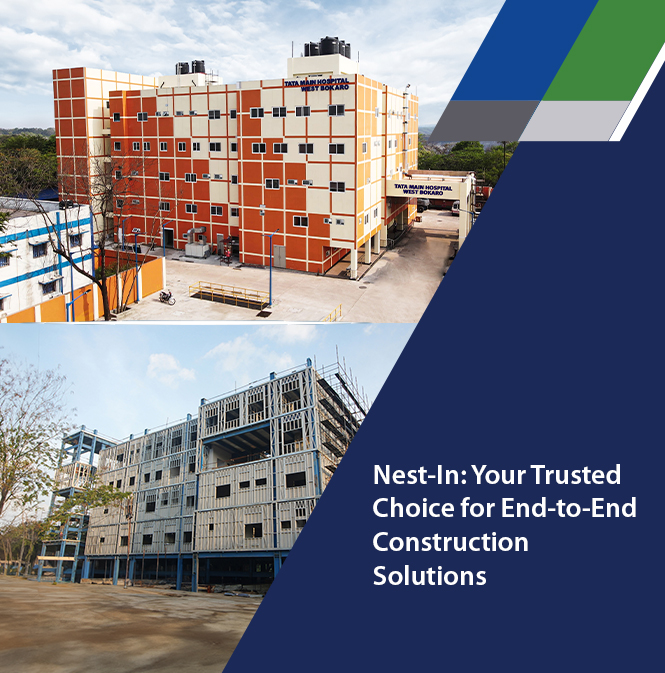

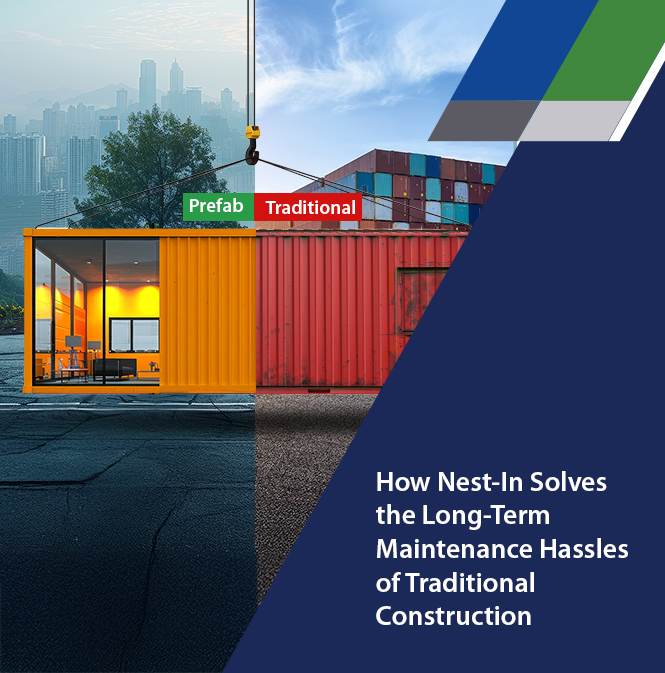

How Nest-In Solves the Long-Term Maintenance Hassles of Traditional Construction

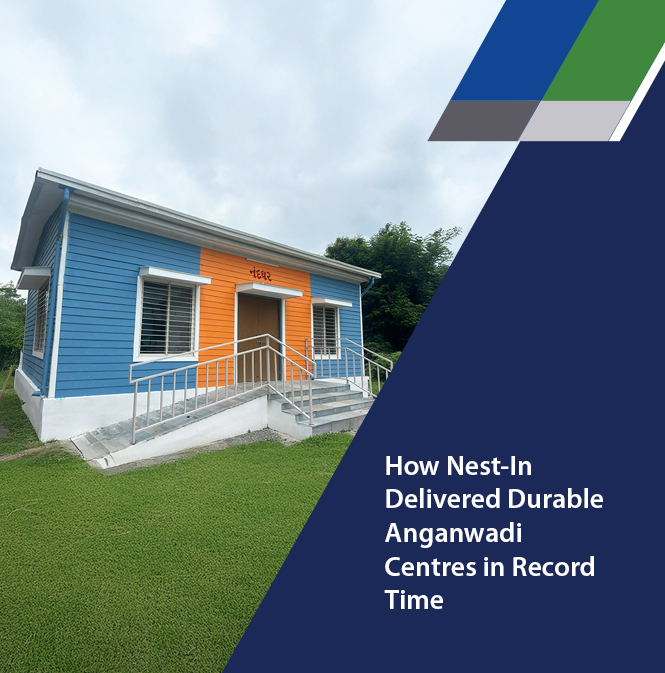

Nest-In from the house of Tata Steel addresses one of the most persistent challenges faced by building owners and organisations: long-term maintenance. Traditional construction often requires frequent upkeep due to inconsistent workmanship, prolonged exposure to weather during construction, and site-dependent variability. These factors can lead to recurring repairs over time.

Nest-In’s prefab construction approach helps address these challenges by shifting most construction activities to controlled factory environments, resulting in precision-built structures that require fewer maintenance interventions throughout their lifecycle.

Reduced Repairs Through Factory-Controlled Precision

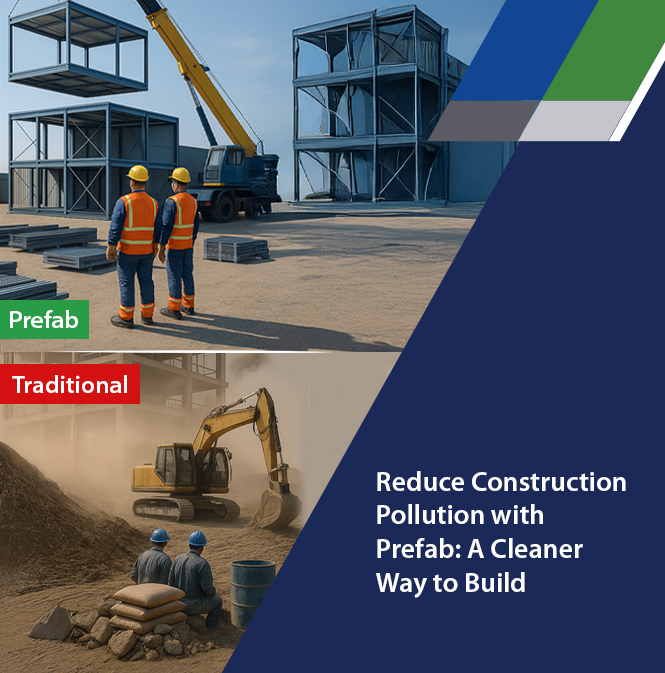

On-site construction is often influenced by uneven material settings, variations in workmanship and changing site conditions, which can lead to cracks, leakages and surface deterioration over time. Prefab building solutions address these challenges by manufacturing building components in factory-controlled environments and under ISO 9001:2015–certified processes.

This ensures quality, precision and dimensional accuracy. By eliminating common construction inconsistencies, prefab construction significantly reduces the likelihood of defects and the need for repeated repairs over the building’s lifecycle.

Durable Materials

Nest-In’s prefab structures are built using premium, corrosion-resistant materials that protect against rust, moisture and environmental exposure. With Tata Steel forming the structural framework, these buildings are engineered for long-term performance across varied climatic conditions—ensuring dependable behaviour even in harsh or humid environments.

Engineered to Withstand Environmental Conditions

Nest-In’s prefab structures are engineered to perform reliably under environmental stresses commonly encountered across regions. Designed to provide earthquake resistance suitable for seismic zones up to zone V, these structures also offer wind resistance up to 240 km/hr and fire resistance of up to 90 minutes, supporting occupant safety and structural integrity during high-risk situations.

This engineered resilience reduces the risk of damage from extreme conditions, helping structures maintain stability over time and significantly lowering the need for corrective maintenance arising from environmental impact.

Reduced On-Site Construction Vulnerabilities

Many long-term maintenance challenges originate during the construction phase. Traditional construction sites are often exposed to weather disruptions, inconsistent labour availability and variable execution practices, all of which can compromise build quality over time. Nest-In’s prefab construction approach addresses these risks by completing a majority of construction activities off-site.

The building components are brought to the site ready for assembly, reducing issues related to improper curing, rushed execution, or prolonged exposure to site conditions. This controlled process results in dependable spaces that maintain structural integrity over time.

Consistency Through Certified Processes

Consistency in construction quality plays a key role in long-term maintenance outcomes. Nest-In follows ISO 9001:2015 certified processes across manufacturing and quality checks. Each building component undergoes systematic inspections before reaching the site. This consistent approach supports reliable performance over the building’s lifespan.

Designed for Long-Term Reliability

Prefab construction is not only about faster project execution but also about predictable performance over time. With factory-controlled manufacturing, accurate detailing and engineered connections, Nest-In’s structures maintain their integrity with fewer maintenance demands.

By limiting exposure to on-site environmental factors during construction, potential defects that typically emerge later in a building’s lifecycle are significantly minimised. This makes prefab construction a dependable choice for a wide range of applications where long-term reliability and uninterrupted operations are essential.

Lower Maintenance Through Better Planning

Many maintenance challenges originate from decisions made during the construction stage. By addressing these factors early through controlled and standardised processes, Nest-In delivers structures designed to remain functional with minimal maintenance intervention.

The use of steel-based construction systems ensures long-term stability and consistency in performance, making prefab construction a practical choice for organisations seeking reliable infrastructure that stands the test of time.

Conclusion

Long-term maintenance issues are often linked to how buildings are constructed. By moving key construction activities to the factory and following structured processes, Nest-In addresses many of the challenges associated with traditional construction methods. The result is a dependable construction approach that supports consistent performance, enhanced durability and reduced maintenance over time.

To explore prefab construction solutions designed for long-term reliability, connect with us at 1800 208 8200 or visit www.nestin.co.in to know more.

Posted in Nest-In on Dec 09, 2025.

Contact Us

Recent Post

How Nest-In Solves the Long-Term Maintenance Hassles of Traditional Construction

How We Built A Zero Energy Building: A Case Study

Zero Energy Building: Redefining India’s Energy-Efficient Future

Addressing the Demand for Durable, Long-Lasting Infrastructure

Rapid Response Infrastructure: Building Fast When Time Matters

Category

- Nest-In 105

- HabiNest 65

- MobiNest 122

- Nestudio 28

- EzyNest 21

- Smart EzyNest 6

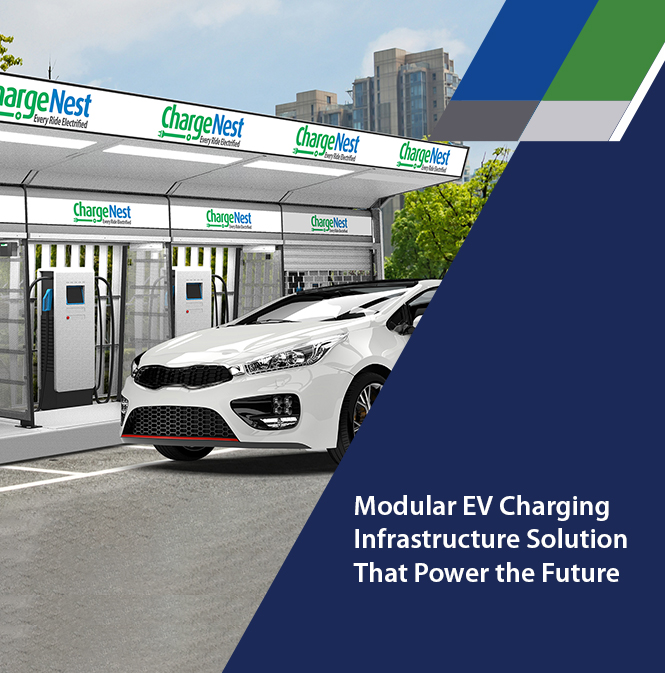

- ChargeNest 7

- Covid Offerings 4

- Brand 7

Add comment