Climate Is Changing. Our Buildings Must Too: How Prefab Creates A Greener, Safer Future

Across Indian cities, deteriorating air quality has become a visible and urgent concern. Repeated instances of severe AQI levels have highlighted how construction-related dust, emissions and on-site activities directly affect public health and urban livability. At the same time, rising temperatures, resource scarcity and environmental degradation are placing greater responsibility on the construction sector to rethink how buildings are constructed.

In this context, the construction sector can no longer rely on conventional building approaches. Reducing dust, conserving water and lowering emissions are no longer optional measures; they are essential requirements for sustainable development.

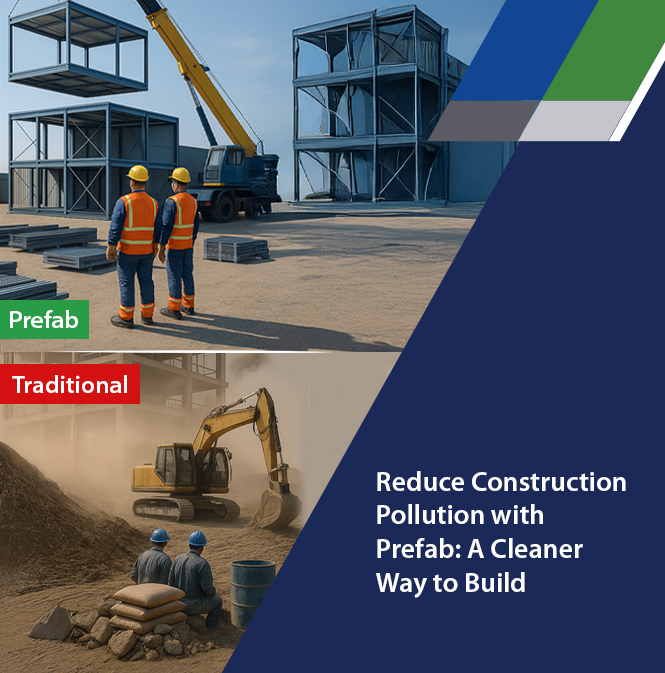

This is where modern methods of construction, such as prefab, gain relevance. By shifting key construction activities into controlled factory environments, prefab construction significantly reduces on-site pollution, improves resource efficiency and supports more sustainable building practices. It represents a forward-looking approach aligned with climate realities, urban air quality challenges and the need for cleaner, more responsible infrastructure development.

Why Traditional Building Methods Strain the Environment

Traditional construction depends heavily on on-site processes that are vulnerable to weather disruptions, manual variability and operational inefficiencies. Inaccurate material handling and frequent rework often lead to excess debris and material waste. Wet construction practices consume large volumes of water and can result in runoff that impacts surrounding land and water bodies.

In addition, continuous movement of machinery and materials contributes to dust, noise and higher carbon emissions. Together, these challenges make it difficult for conventional construction practices to consistently support large-scale green building objectives.

Prefab Construction: A Smarter Way to Build

Prefab construction introduces greater discipline and predictability into the building process. Building components are manufactured in factory-controlled environments, ensuring precision, consistency and efficient use of resources through standardised processes and quality checks.

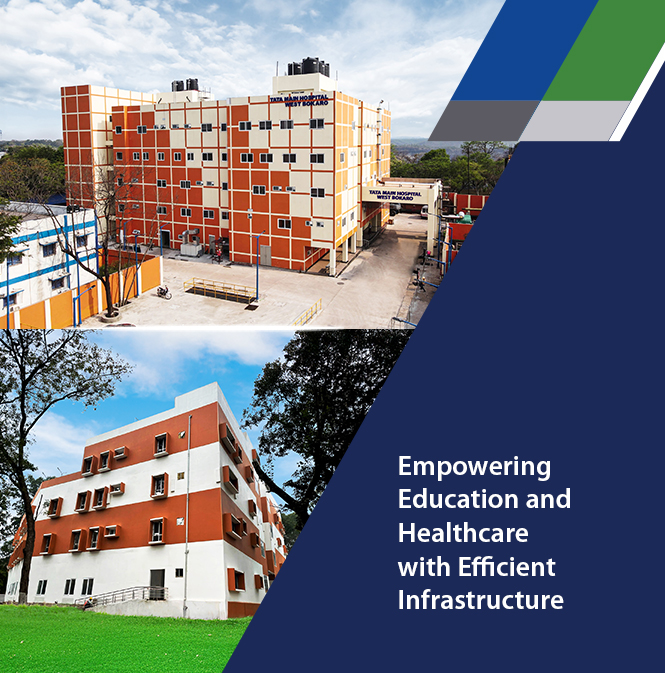

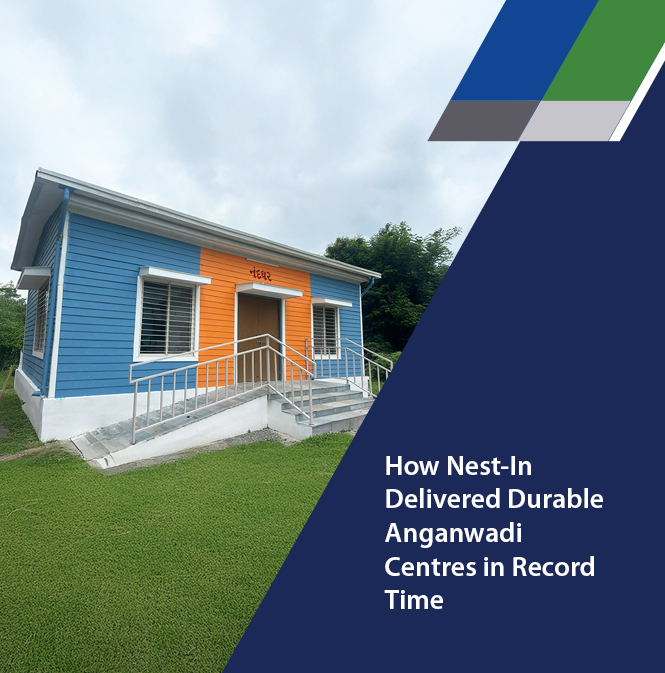

Nest-In from the house of Tata Steel brings this approach to life through prefab construction solutions designed to prioritise controlled execution, reduced waste and environmentally responsible outcomes. By reducing dependence on site-intensive activities, projects progress with fewer disruptions, faster timelines and a significantly lower environmental footprint.

Material Efficiency Through Off-Site Production

One of the most significant sustainability advantages of prefab construction lies in material optimisation. Factory-controlled manufacturing allows for precise cutting, standardised processes and consistent quality control. This, in return, significantly reduces excess material usage and waste generation. Regular quality checks at each stage further minimise errors that typically result in rework at traditional construction sites.

As a result, prefab construction supports more efficient use of materials and cleaner project sites. This controlled, off-site construction approach directly contributes to eco-friendly construction practices by reducing unnecessary resource wastage throughout the building lifecycle.

Minimum Water Usage and Lower Emissions

Prefab construction supports greener building practices through significant reductions in water consumption and emissions. The construction process is largely dry above ground, with water used primarily during foundation work, resulting in a 48% reduction in freshwater usage.

Optimised factory-based manufacturing reduces material consumption by 65%. In addition to this, the prefab construction approach lowers greenhouse gas emissions by 53%. These measurable outcomes help projects align more closely with long-term green building goals while addressing growing environmental concerns.

Lower On-Site Disruption and Safer Sites

With factory-manufactured building components, on-site activity is significantly shorter, more controlled and better organised. Reduced dependence on heavy machinery and fewer vehicle movements help minimise dust, noise and carbon emissions.

Lower labour requirements and limited on-site operations further enhance safety conditions while reducing disruption to surrounding areas. This makes prefab construction well-suited for a wide range of applications, from spaces being built in rural settings to dense urban regions, where site sensitivity is a key consideration.

Building Responsibly for the Future

As climate pressures continue to rise, construction practices must evolve to prioritise resilience and responsibility. Prefab construction offers a practical response by conserving resources, reducing pollution and improving safety. Factory-controlled manufacturing and efficient execution make prefab a necessary shift in how the built environment responds to growing climate challenges.

To explore how Nest-In’s prefab construction solutions can support your sustainability goals and enable you to build future-ready spaces, connect with us at 1800 208 8200 or visit www.nestin.co.in to know more.

Posted in Nest-In on Dec 17, 2025.

Contact Us

Recent Post

Climate Is Changing. Our Buildings Must Too: How Prefab Creates A Greener, Safer Future

Built for Emergencies: Why Modular Construction Is Ideal for Rapid Disaster-Relief Infrastructure

How Nest-In Solves the Long-Term Maintenance Hassles of Traditional Construction

How We Built A Zero Energy Building: A Case Study

Zero Energy Building: Redefining India’s Energy-Efficient Future

Category

- Nest-In 106

- HabiNest 65

- MobiNest 123

- Nestudio 28

- EzyNest 21

- Smart EzyNest 6

- ChargeNest 7

- Covid Offerings 4

- Brand 7

Add comment