The Harmful Effects Of Construction Waste On The Environment And What We Can Do About It

Piles of rubble encroaching the pavements. Mounds of construction materials being dumped on the roadside. Dirt and debris from the demolitions spilling onto the streets from the uncovered, unfenced construction sites.

All of the above are common sights across India - be it a small town or metro cities. In fact, the capital of our country is infamous for facing severe air pollution crises over the years. While car emissions, burning of crops, and power plant stations have been blamed for poisoning the city air, one of the most dangerous culprits often escaped the attention of the environmental groups - construction waste.

The capital city’s construction sites – especially those along the Eastern and Southern fringes of the city - and the production of the raw materials used in construction (such as bricks and concrete) heavily add to the toxicity of air that, according to physicians, is making Delhi increasingly more hazardous, particularly for children and the elderly. As per the Delhi Pollution Control Committee (DPCC) officials, 30 percent of air pollution is caused by the dust coming from construction sites.

Related Article - THE HARMFUL EFFECTS OF CONSTRUCTION WASTE ON THE ENVIRONMENT AND WHAT WE CAN DO ABOUT IT

According to a 2015 study, antiquated construction standards, practised across thousands of building sites, fill up the air with a huge amount of coarse pollutants. This phenomenon, in turn, is strongly linked to heart disease.

However, Delhi is not the only city to be suffering from the onslaught of construction waste; the situation is more-or-less the same across the Indian subcontinent. Construction activities result in the accumulation of huge amounts of solid waste, comprising concrete chunks, stones, sand, gravel, bricks, wood, and event glass, metal and the worst one – plastic. As a result, the management of construction waste has become a big headache for urban planners, nationwide. Moreover, diminishing availability of dumping sites on the one hand and ever-increasing volume of rubble, on the other hand make the situation even more critical. No wonder, the waste disposal expenses are on the rise.

According to some estimates from the Central Pollution Control Board, India generates a whopping 48 million tons solid waste per annum of which waste from Construction Industry accounts for 25%. Such a high quantum of waste puts enormous pressure on cities’ waste management systems.

The mountains of debris created through traditional construction practices eventually transform into massive waste at landfills, further causing soil pollution. Eventually, all these harmful debris are carried away by the rainwater. Construction sites often produce hazardous waste such as mercury, lead, aerosol cans, and more. The heap comprising of hazardous waste is often burnt after the completion of construction, emitting unhealthy and toxic fumes into the air.

Can banning construction be a solution?

NO.

Construction is the backbone of infrastructural development, and construction work cannot be stalled for a long time. This highly employment-intensive sector accounts for a lion’s share of the country’s capital investment on a year-over-year basis. Further, suspending an ongoing construction project can also lead to negative consequences. Discarding a construction project midway leaves the site in a pathetic state, with the leftover debris further polluting the environment and making matters worse.

What is the way out then?

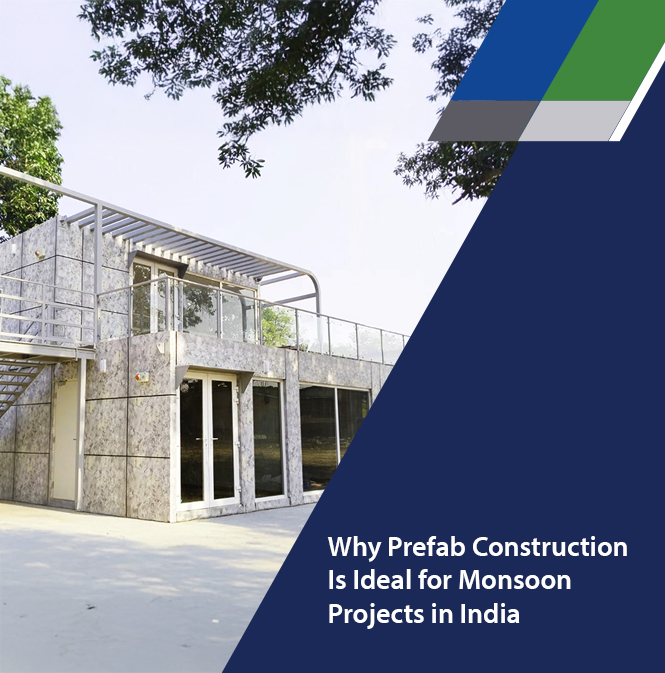

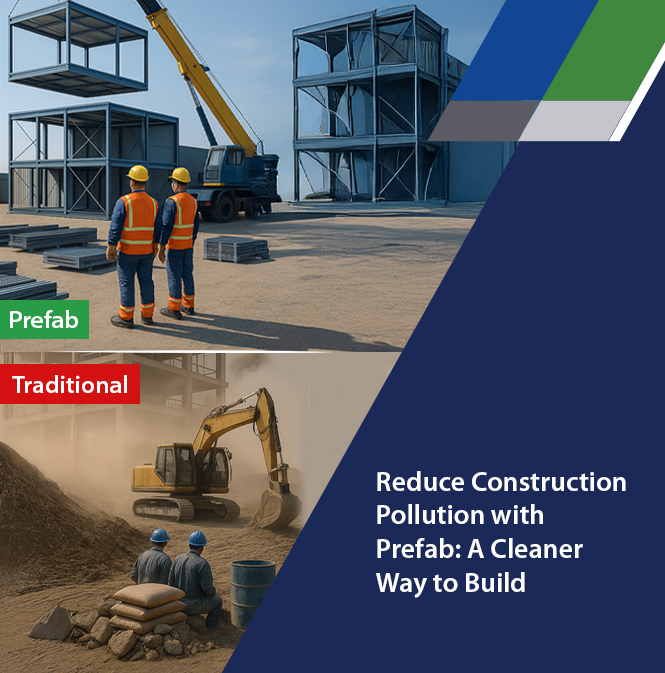

Embracing innovative construction and adopting alternate construction methods powered by off-site, prefabricated technology can be an effective way to significantly minimize construction waste from the equation. In the case of prefabricated construction, individual modules and components are fabricated in a controlled factory environment. The finished modules are then transported to the construction site and assembled to form a building of as per the design requirements. In fact, as the blueprints are detailed to the last millimetre, there is minimal wastage of resources that is an expected feature in conventional brick-and-mortar construction.

Related Article - THE NEW GREEN APPROACH FOR LIVING

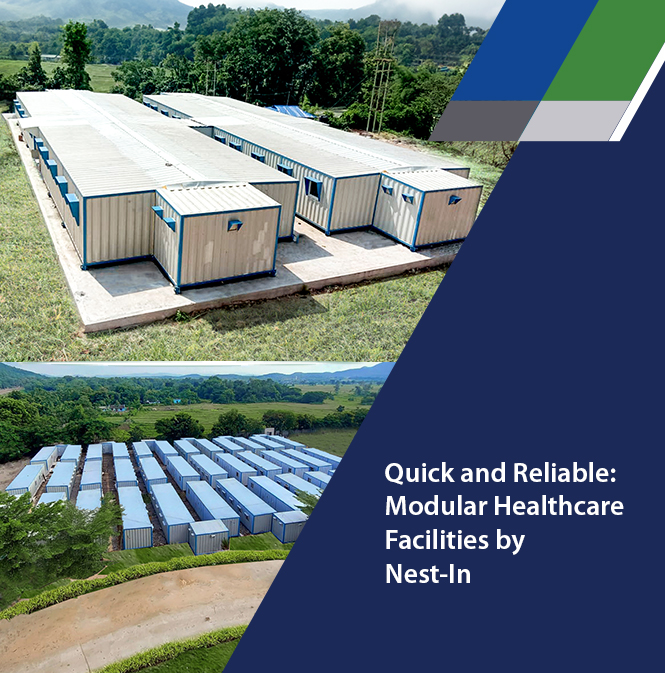

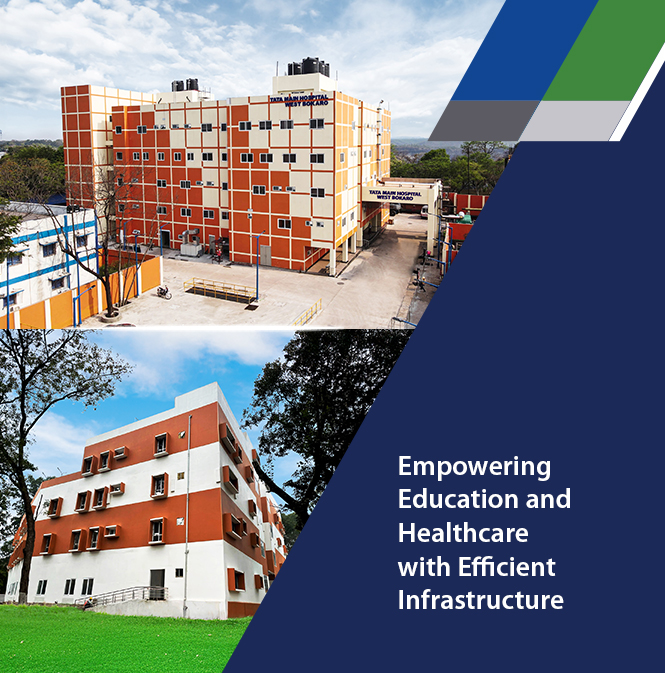

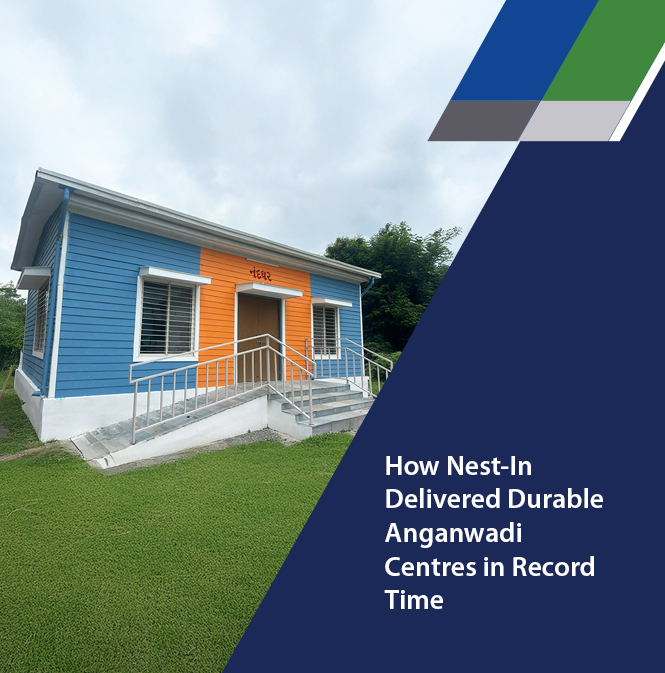

At Nest-In, we offer steel based prefabricated construction solutions which can be used in multiple sectors ranging from real estate to hospitality and from sanitation to military infrastructure. Our construction solution offerings include seven brands, namely Nestudio, HabiNest, EzyNest modular toilets, Smart EzyNest, CanvaNest, AquaNest and Mobinest. These modular solutions help minimize construction waste as fewer raw materials are handled on the building site. Made of light gauge steel frames, these solutions also help save on building load. What’s more? As the components are made of steel, they can easily be recycled, leading to less waste ending up in our landfills.

Contact Us

Recent Post

How We Built A Zero Energy Building: A Case Study

Zero Energy Building: Redefining India’s Energy-Efficient Future

Addressing the Demand for Durable, Long-Lasting Infrastructure

Rapid Response Infrastructure: Building Fast When Time Matters

Reduce Construction Pollution with Prefab: A Cleaner Way to Build

Category

- Nest-In 104

- HabiNest 65

- MobiNest 122

- Nestudio 28

- EzyNest 21

- Smart EzyNest 6

- ChargeNest 7

- Covid Offerings 4

- Brand 7

Add comment